Research - (2022) Volume 13, Issue 4

Development of bioresorbable braided self expanding implantable neurovascular flow diverter for intracranial aneurysm

Pramod Kumar,

Kothwala Deveshkumar Mahendralal* and

Durani Mohamadovesh Mohamadyasin

Meril Life Sciences Pvt. Ltd, Bilakhia House, Muktanand Marg Chala, Vapi, Valsad, 396 191, Gujarat, India

*Correspondence:

Kothwala Deveshkumar Mahendralal, Meril Life Sciences Pvt. Ltd, Bilakhia House, Muktanand Marg Chala, Vapi, Valsad, 396 191,

Gujarat,

India,

Email:

Received: 30-Mar-2022, Manuscript No. ipjnn-22-12698;

Editor assigned: 02-Apr-2022, Pre QC No. P-12698;

Reviewed: 19-Apr-2022, QC No. Q-12698;

Revised: 23-Apr-2022, Manuscript No. R-12698;

Published:

30-Apr-2022

Abstract

An intracranial aneurysm can be treated with an implantable self- expanding ultrathin bioresorbable neurovascular device. Inside the intracranial aneurysm, the braided self-expanding bioresorbable neurovascular implanted device obstructs the blood flow to enter inside an aneurysm. The biocompatible and totally bioresorbable ultrathin braided mesh structure with a specified braiding arrangement and reduced pore size that redirects blood flow to limit blood flow inside aneurysm sac. A braided neurovascular implant with an elastomeric compound coating provides sufficient radial strength, axial flexibility, and excellent self-expanding capabilities. The self-expandable bioresorbable braided scaffold retains structural integrity for about a year before resorbing over a two- to three-year time frame

Keywords

Self expanding bioresorbable; Neurovascular; Aneurysm.

Introduction

Aneurysms can be caused by a number of factors, including

high blood pressure and atherosclerosis, trauma, genetics,

and irregular blood flow. A gigantic aneurysm can be more

than 2.5 centimetres wide and include more than one artery.

High blood pressure (hypertension) causes damage and

weakening of blood vessels over time [1]. The formation of

fatty plaques (atherosclerosis) causes a weakening of the blood

vessel wall. Inherited illnesses that cause blood vessel walls to

be weaker than usual. A gigantic aneurysm can be more than

2.5 centimetres wide and include more than one artery [2].

The anterior (carotid) circulation accounts for approximately

86.5 percent of all cerebral Aneurysms. An infected arterial

wall causes a mycotic aneurysism - an abnormal bulge on the

inside of an artery. For more than 40 years, surgical clipping

has been performed to treat cerebral aneurysms. Aneurysm

clipping and endovascular procedures like as coiling, stentassisted

coiling, and flow diversion stents are two of the most

common treatment choices. A ruptured cerebral aneurysm

prognosis is determined by the aneurysm size and location, as

well as the patient age, health, and neurological status [3,4].

An aneurysm is a ballooning at a weak spot in an artery wall.

An aneurysm walls can be thin enough to rupture. Early

bleeding from a burst brain aneurysm can kill some people.

A bad outcome, death or lifelong impairment affects around

two third of patients. It is an endovascular procedure that

entails introducing a micro catheter into the femoral artery.

Instead of introducing a device inside the aneurysm sac, as

with coiling, a device is placed in the main blood vessel to

divert flow of blood away from the aneurysm. In present

treatment, the use of a self-expanding non degradable flow

diverter has drawbacks such as corrosion and toxicity in the

implant location. Present work also pertains to a process for

producing a bioresorbable flow diverter for neurovascular

implants that has high strength, great flexibility, and a small

pore size [5]. This is more especially connected to employing

PLLA or PLGA material to fabricate tubular braid devices.

The braided construction with smaller pore sizes helps to

divert the blood flow and prevent blood from penetrating

the aneurysm sac. The treatment of intracranial aneurysms

with devices by covering the aneurysm neck. Mechanisms of

the delayed rupture are actually not completely elucidated.

Very late thrombosis of the flow diverter is possible and

long term follow up of treated patients is certainly required.

Combinations of the bioresorbable filaments can also be

used to make braided tubes. Another potential mechanism involves intra aneurysm thrombosis created by flow diversion

which can be associated with an inflammatory reaction.

Materials and Methods

The micro porous bioresorbable braided tube with open

and closed angle provides high strength, flexibility and

a small pore size. The groups of several shape memory

polymers such as Poly L- lactide-co-caprolactone (PLC),

Poly caprolactone (PCL), Poly - dl -lactic acid (PDLLA),

Poly glycerol Sebacate (PGS), Poly L-lactide (PLLA),

Poly glycolic Acid (PGA), Poly L- lactide co- glycolic acid

(PLGA) or mixture therefore used in the braiding process.

The extruded monofilament is annealed for allowing it to

endure high tension braiding. The implant is coated with

bioresorbable elastomer [6]. Heat treatment was carried

out under vacuum conditions. An anti-thrombogenic,

anti-inflammatory, or any specific hormonal drug is

coated on an elastomers coated flow diverter device. The

microporous braided bioresorbable implant was made with

20-50 micron monofilaments and a 32-96 carrier braiding

machine. Each implant has a porosity of about 24 to 120.

Many filaments are braided together over a mandrel with

braiding angles ranging from 30°C to 200°C. The pores

formed by the braiding pattern span from 12 to 30 pores

per millimeter [7-9]. The flow diverter braiding angle is

inversely proportional to the pore size. PET mandrels are

held in a controlled vacuum and annealed at a temperature

ranging from 90°C to 130°C, for a period of time ranging from 14 to 20 hours. The polymer braided tube is fixed

on a mandrel at both ends and then annealed to stabilize

the braided structures. Braided mandrels are kept under

vacuum in a controlled environment of 500-800 mm Hg

pressure. Annealing is a process in which the body is held at

a temperature between 90°C to 130°C for 12 to 20 hours.

The terminal annealing, on the other hand, is carried out

from 1 to 5 hours with a temperature of 90°C to 110°C.

The other forty six monofilaments are employed with the

two 20-50 micron platinum tungsten monofilaments are

used for each marker, with an elastomer coating thickness

ranging from 1 to 10 m. The internal diameter of the marker

is 35-45 microns, while the wall thickness is 2-5 microns

[10]. Each marker is 0.1-0.2 mm long or as specified by

the braided construction. A flow diverter with elastomeric

coating was packed in vacuum desiccators for 8-20 hours at

room temperature and then cured between 70°C to 140°C.

The radial strength of non-elastomers coated braided tube

ranged from 5 to 20 N, but increased from 20 to 30 N,

when it was braided with the coating. The distance between

the braided flow diverter and the spray gun should be kept

between 2 to 4 cm and rotation should be between 20 to

30 rpm, which is important in achieving a smooth and

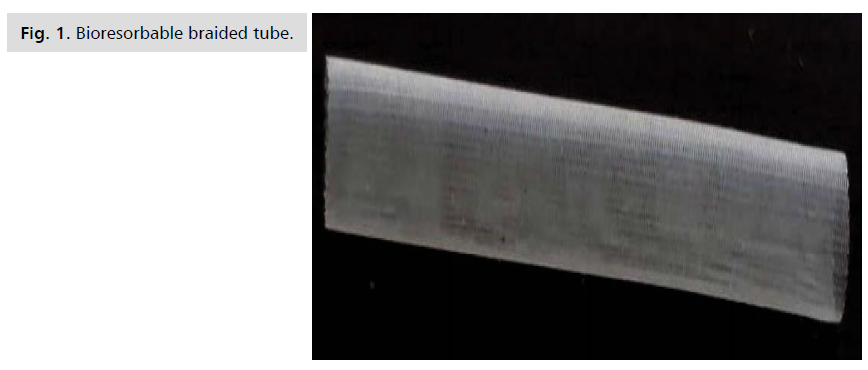

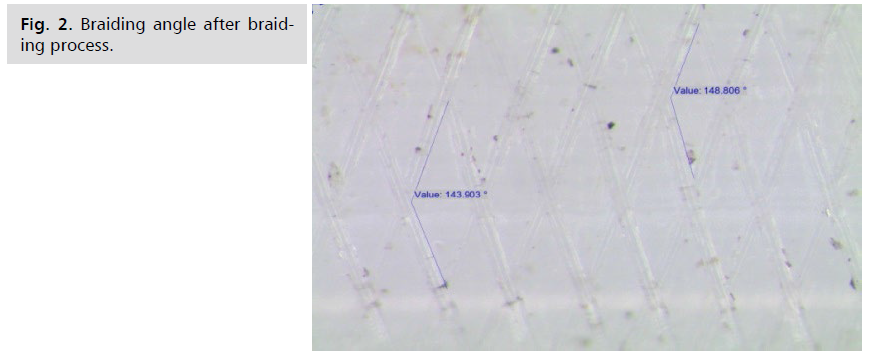

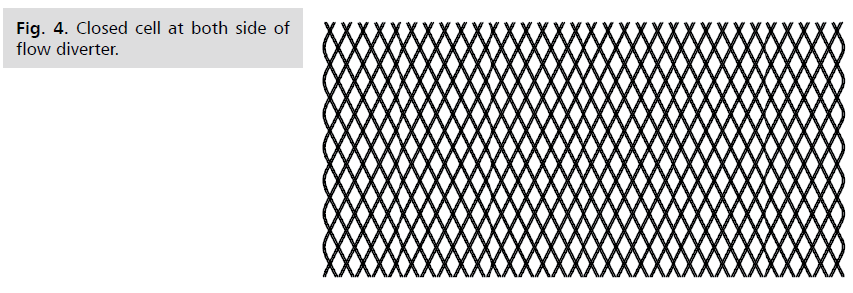

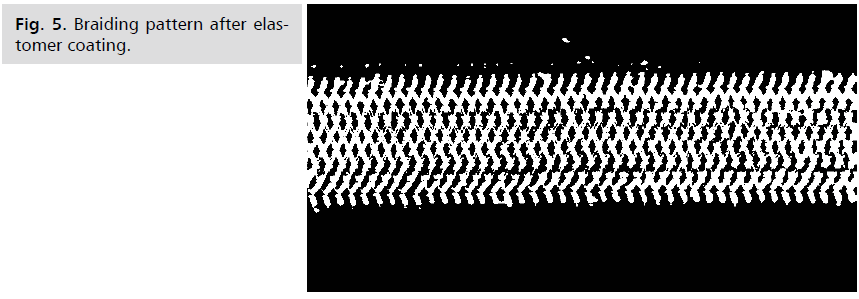

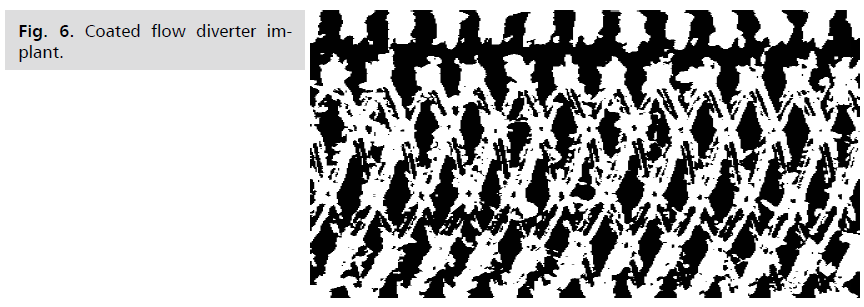

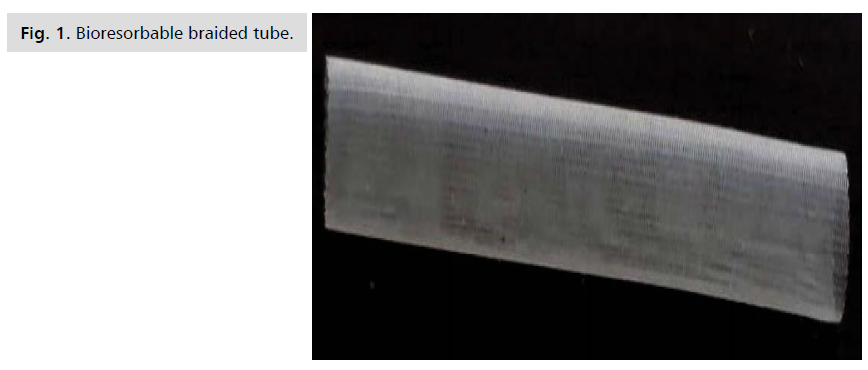

uniform coating (Fig. 1-6).

Fig 1: Bioresorbable braided tube.

Fig 2: Braiding angle after braiding process.

Fig 3: Open cell at both side of flow diverter.

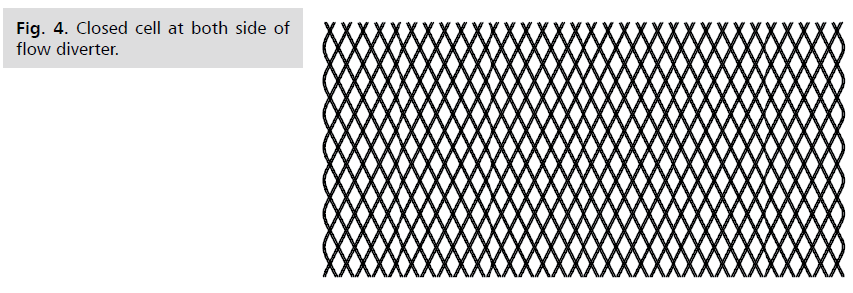

Fig 4: Closed cell at both side of flow diverter.

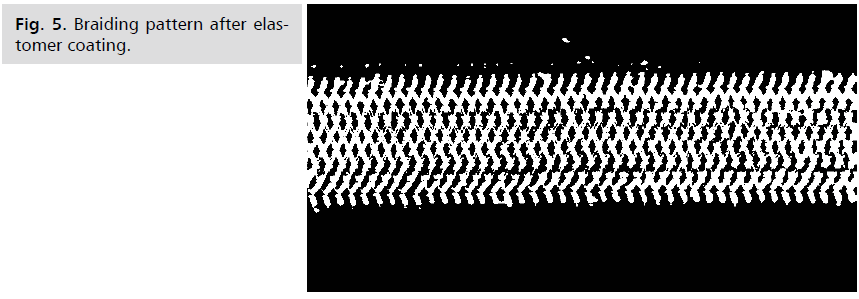

Fig 5: Braiding pattern after elastomer coating.

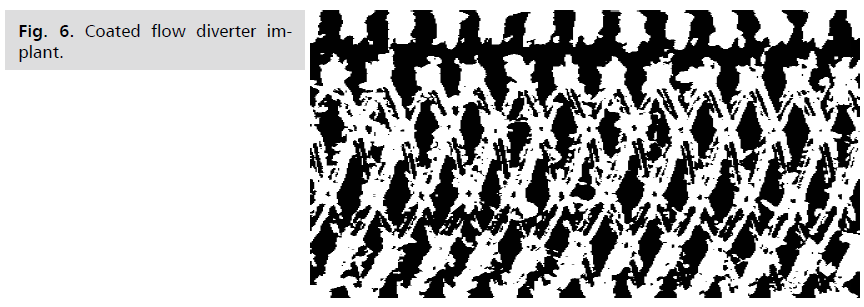

Fig 6: Coated flow diverter implant.

Results and Discussion

Intracranial aneurysm stenting is a procedure that involves

redirecting and rerouting the arterial blood flow and creating a way to avoid rupture of aneurysm to prevent

blood from entering the brain [11,12]. The microporous

braided implant incorporates small pores of bioresorbable

material with particular braiding structure, resulting in

sufficient radial strength, foreshortening, and other selfexpanding

stent properties. The initial annealing procedure

aids in the elimination of monomer and the relaxation of

internal stress in braided monofilament [13]. The flow

diverter braided mesh angle has a direct impact on its

pore size and as a result, radial stiffness which is a critical characteristic determining the integrity and structure

after being inserted into the body lumen. Annealing of

the braid cross wire by lowering the melting point of the

polymer increases the mechanical strength of the braided

arrangement and allows for a comparable configuration

following deployment in the artery lumen. The analytic

evidence presented here clearly demonstrates that the

micro porous structure maintains its properties throughout

the operation [14].

Sample results

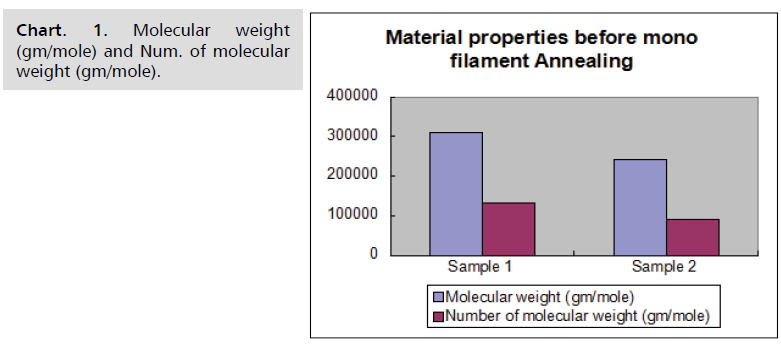

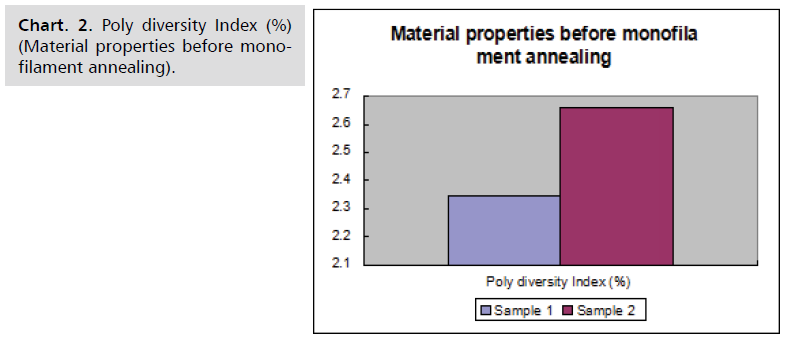

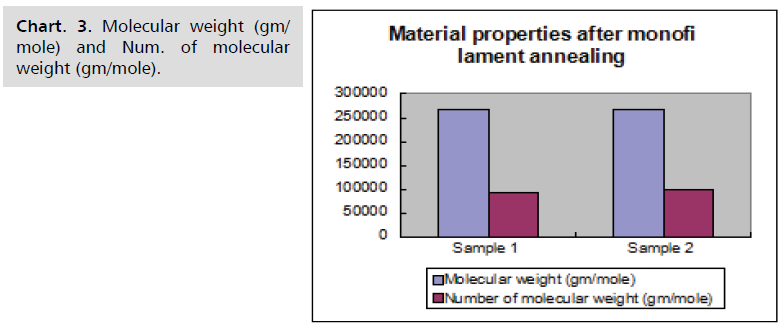

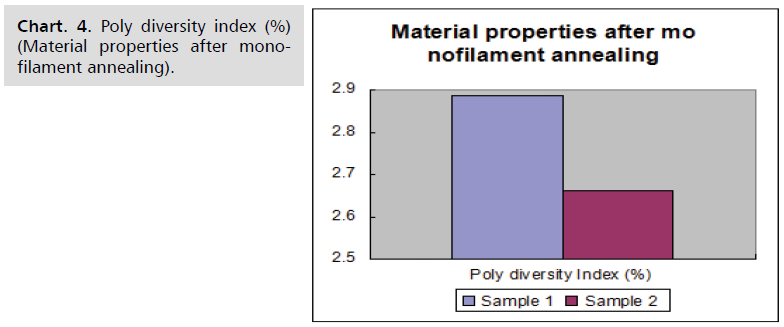

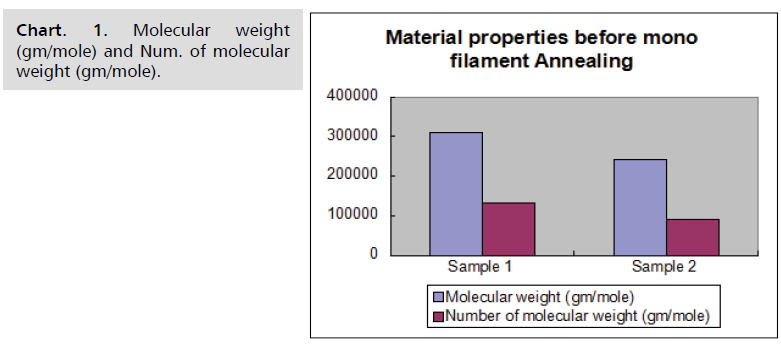

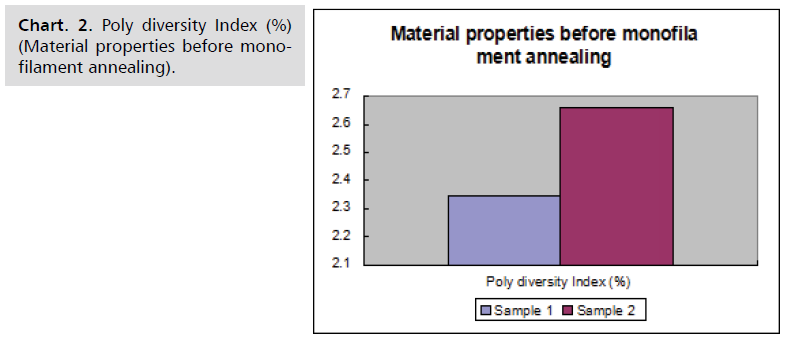

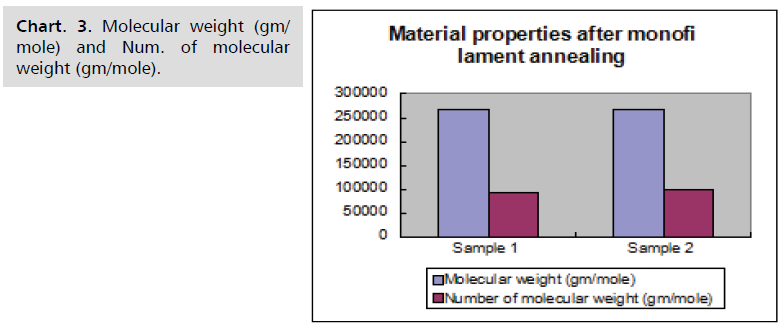

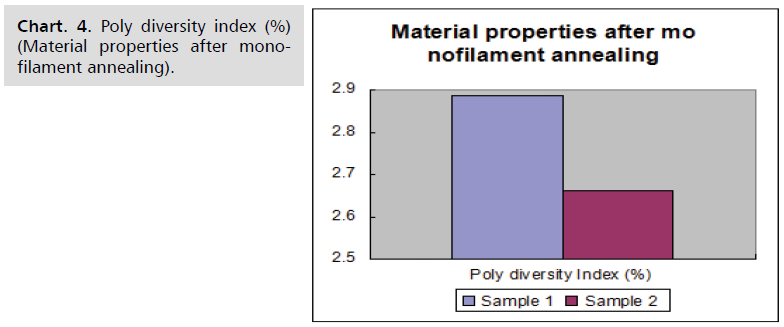

Material characteristics of samples before and after

monofilament annealing are given in following Chart. 1-4.

Chart. 1. Molecular weight (gm/mole) and Num. of molecular weight (gm/mole).

Chart. 2. Poly diversity Index (%) (Material properties before monofilament annealing).

Chart. 3. Molecular weight (gm/mole) and Num. of molecular weight (gm/mole).

Chart. 4. Poly diversity index (%) (Material properties after monofilament annealing).

The material properties of BRS flow diverter without coating shown in below Tab. 1.

| Material Properties after Annealing of BRS Flow Diverter (without coating) |

| Sample Details |

Sample-1 |

Sample-2 |

| Molecular weight (gm/mole) |

377678 |

402250 |

| Number of molecular weight (gm/mole) |

160340 |

211278 |

| PDI (Polydispersity Index) |

2.355 |

1.904 |

| Glass transition temperature (°C) |

57.26 |

53.13 |

| Melting temperature (°C) |

187.36 |

187.46 |

| % Crystallinity |

64.30 |

68.50 |

| Radial strength of BRS flow diverter |

9.25 N, 9.17 N, 10.96 N |

Tab. 1. Material properties after annealing of BRS flow diverter (without coating).

The material properties of BRS flow diverter was coated

with elastomeric coating, which given the following results

(Tab. 2).

| Material Properties after Elastomeric Coating of BRS Flow Diverter |

| Sample Details |

Sample-1 |

Sample-2 |

| Molecular weight (gm/mole) |

345856 |

335633 |

| Number of molecular weight (gm/mole) |

145567 |

133464 |

| PDI (Polydispersity Index) |

2.376 |

2.515 |

| Glass transition temperature (°C) |

60.19 |

50.71 |

| Melting temperature (°C) |

187.35 |

187.16 |

| % Crystallinity |

62.30 |

63.40 |

| Radial strength of BRS flow diverter |

84.73 N, 87.90 N, 67.76 N |

Tab. 2. Material properties after elastomeric coating of BRS flow diverter.

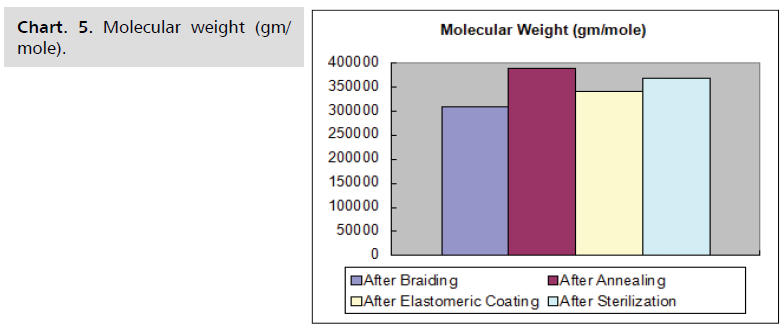

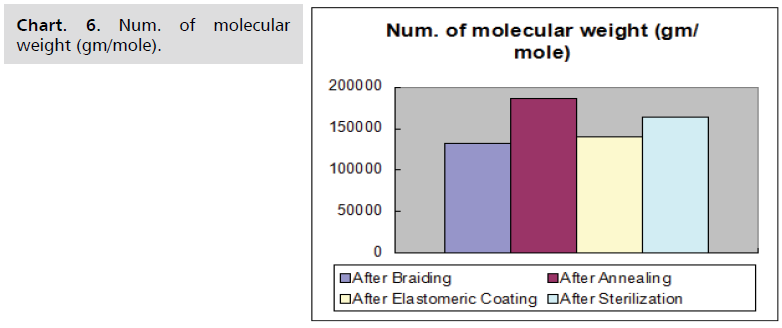

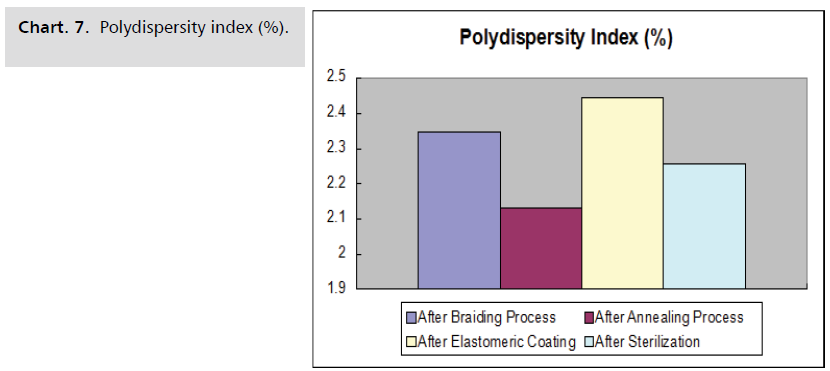

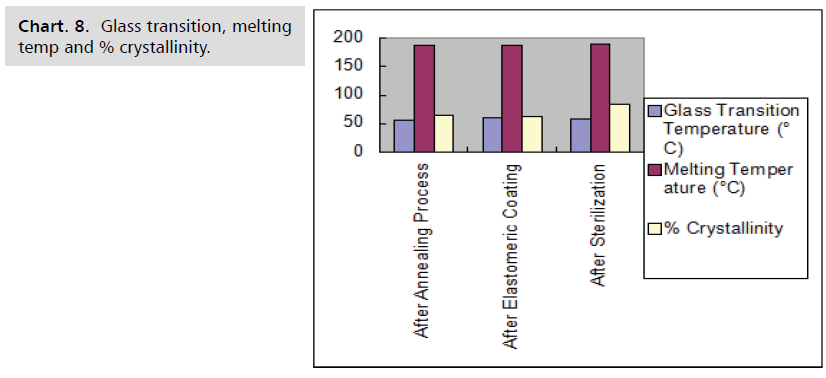

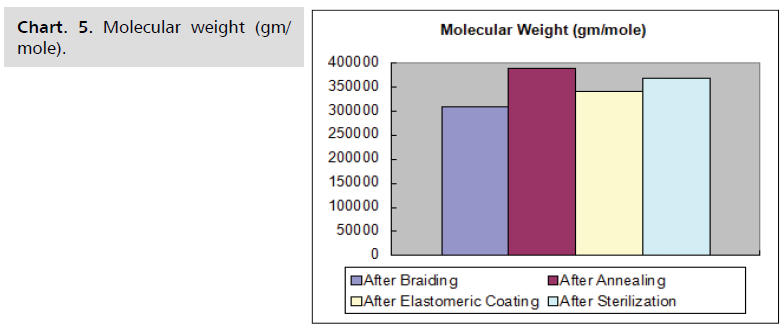

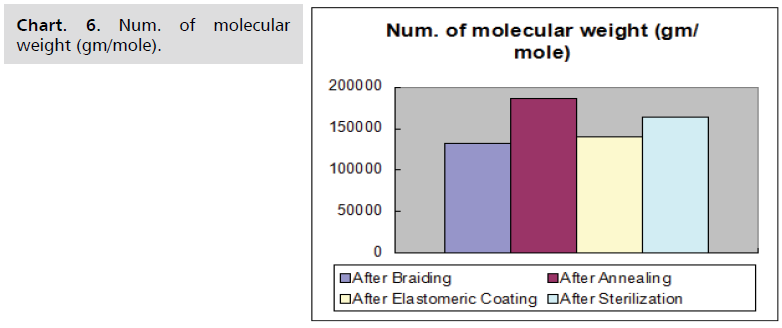

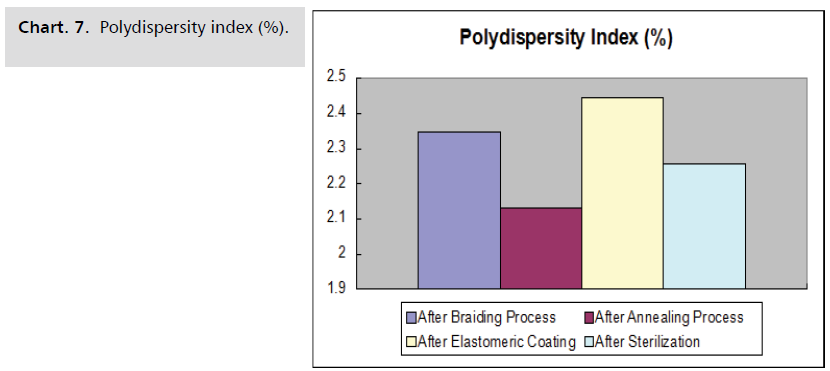

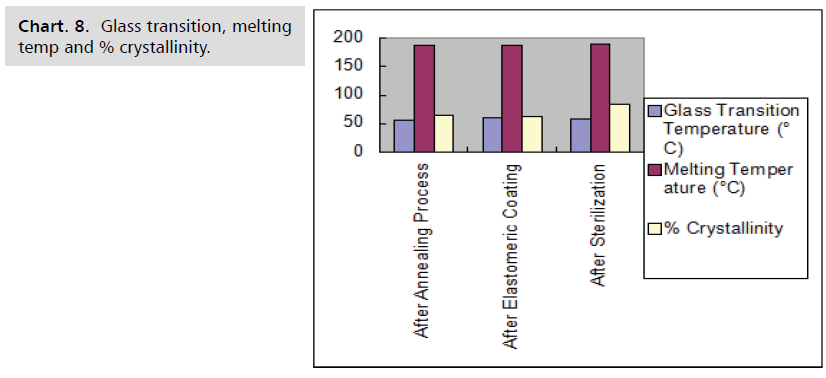

Process sample results

The properties of polymer, such as molecular weight,

number of molecular weights, polydispersity index (PDI),

glass transition temperature, melting temperature, and

percent crystallinity, do not change when the polymer

is exposed to different process parameters - such as

temperature and time shows in the Chart. 5-8.

Chart. 5. Molecular weight (gm/mole).

Chart. 6. Num. of molecular weight (gm/mole).

Chart. 7. Polydispersity index (%).

Chart. 8. Glass transition, melting temp and % crystallinity.

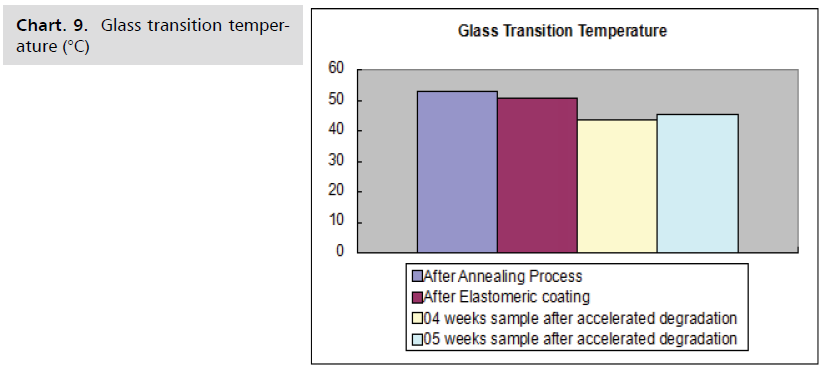

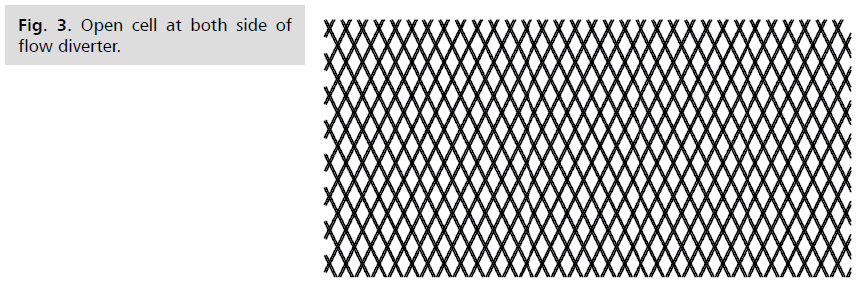

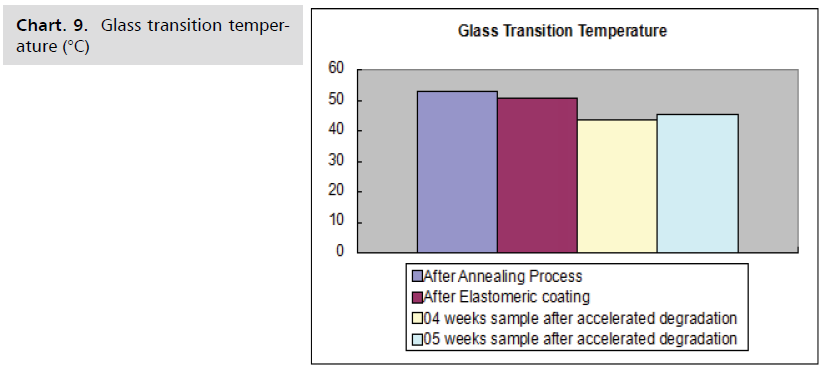

Degradation process result

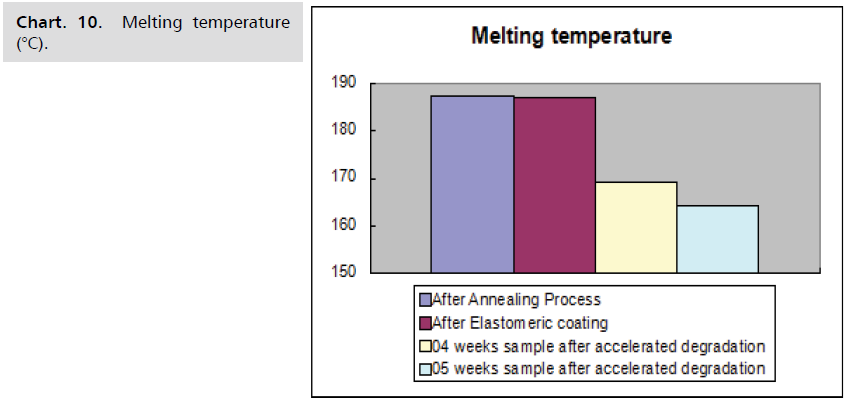

The following Charts. 9-11 shows, when a flow diverter

is subjected to accelerated degradation, the parameters of

the polymer, such as glass transition temperature, melting

temperature, and % crystallinity, steadily decrease with

time.

Chart. 9. Glass transition temperature (°C)

Chart. 10. Melting temperature (°C).

Chart. 11. % crystallinity.

New degradation data in in vitro condition

The following chart shows the accelerated in vitro

simulation study at 70°C interval days.

Conclusion

The treatment of intracranial aneurysms with flow

diverters seems to be highly efficacious. A bioresorbable

ultrathin braided mesh structure with a smaller pore size redirects blood flow to prevent blood from flowing into

an aneurysm. The safety of this treatment appears to be

satisfactory, specifically in the context of treating complex

aneurysm. Flow diverters have been proposed for use in

very small ruptured aneurysms that are untreatable using

standard endovascular techniques. Bioresorbable materials

are thought to be safer and more biocompatible. The

biodegradable solution could meet the short-term needs of

a sick patient while avoiding the long-term risks of dense

metal mesh.

REFERENCES

- Jamshidi M, Rajabian M, Avery MB, et al. A novel self-expanding primarily bioabsorbable braided flow-diverting stent for aneurysms: initial safety results. J Neuro Interv Surg. 2020; 12(7):700-705.

Google Scholar, Crossref, Indexed at

- Howe C, Mishra S, Kim YS, et al. Stretchable, implantable, nanostructured flow-diverter system for quantification of intra-aneurysmal hemodynamics. ACS Nano. 2018;12(8):8706-8716.

Google Scholar, Crossref, Indexed at

- Henkes H, Weber W. The past, present and future of endovascular aneurysm treatment. Clin Neuroradiol. 2015;25(2):317-324.

Google Scholar, Crossref, Indexed at

- Panchendrabose K, Muram S, Mitha AP. Promoting endothelialization of flow-diverting stents: a review. J Neurointer Surg. 2021;13(1):86-90.

Google Scholar, Crossref, Indexed at

- Kallmes DF, Ding YH, Dai D, et al. A new endoluminal, flow-disrupting device for treatment of saccular aneurysms. Stroke. 2007;38(8):2346-2352.

Google Scholar, Crossref, Indexed at

- Pai AM, Kameda-Smith M, van Adel B. A review of recent advances in endovascular therapy for intracranial aneurysms. Crit Rev Biomed Eng. 2018;46(4):369-397.

Google Scholar, Crossref, Indexed at

- Ignacio A, Sarabia R, Pintado R, et al. Flow-diverter devices for intracranial aneurysms: systematic review and meta-analysis. Neurosurg. 2013;73(2):193-200.

Google Scholar

- Chen Y, Howe C, Lee Y, et al. Microstructured thin film nitinol for a neurovascular flow-diverter. Sci Rep. 2016;6:23698.

Google Scholar, Crossref, Indexed at

- Giacomini L, Piske RL, Baccin CE, et al. Neurovascular reconstruction with flow diverter stents for the treatment of 87 intracranial aneurysm: Clinical results. Interv Neuroradiol. 2015;21(3):292-299.

Google Scholar, Crossref, Indexed at

- Pierot L. Flow diverter stents in the treatment of intracranial aneurysms: Where are we? J Neuroradiol. 201;38(1):40-46.

Google Scholar, Crossref, Indexed at

- Indolfi C, De Rosa S, Colombo A. Bioresorbable vascular scaffolds — basic concepts and clinical outcome. Nat Rev Cardiol. 2016;13(12):719-729.

Google Scholar, Crossref, Indexed at

- Uurto I, Mikkonen J, Parkkinen J, et al. Drug-eluting biodegradable poly-D/L-lactic acid vascular stents: an experimental pilot study. J Endovasc Ther. 2005;12:371-379.

Google Scholar, Crossref, Indexed at

- Arat A, Daglioglu E, Akmangit I, et al. Bioresorbable vascular scaffolds in interventional neuroradiology. Clin Neuroradiol. 2018;28(4):585-592.

Google Scholar, Crossref, Indexed at

- Joost DV, Jeroen B, Anouk VN, et al. New generation of flow diverter (Surpass) for unruptured intracranial aneurysms. Stroke. 2013;44:1567-1577.

Google Scholar, Crossref