Keywords

Alginate; Disinfection; Orthodontic stone models; 3-D scanning

Introduction

Fixed mechanics and removable appliances are the main components of modern orthodontic treatment. These components are applied at different stages of treatment for various purposes such as tooth movement or retention. In order to make some orthodontic mechanics like removable appliances or lingual retainers, a dental stone model is needed. Alginate impression materials are widely used to produce stone models, although some new digital impression-taking devices have been developed. Alginate impression materials have many advantages, such as their ease of use and low cost, but their main disadvantage is dimensional instability [1-6]. Disinfection of alginate impressions is the one of the main processes in dental clinics and laboratories for proper infection control [7,8]. The main methods for disinfection are spraying alginate impressions with disinfectants or immersing alginate impressions into disinfectants [9,10]. However, immersion or spraying of alginate impressions with those solutions reportedly compromises the dimensional accuracy and surface quality of the resultant stone models. There are also several other factors that may influence the accuracy of dental casts such as the type of impression material, impression technique, type of tray used, casting materials, storage condition andtime, and disinfectant procedures for impressions which require further investigation for proper use [11,12].

This study investigated the effects of impression materials and types of disinfectants used on the accuracy of stone models.

Materials and Methods

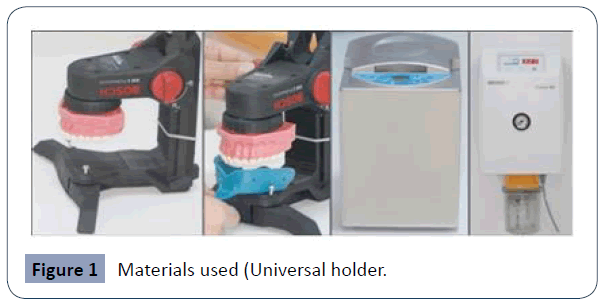

The materials used in the study are displayed in Table 1. A device called Dento (BM1 professional, Bosch, Germany) that simulates the mouth was designed and produced by combining a maxillary typodont and a universal holder for a standard impression. The position of the impression tray on the universal holder was stabilized with the help of two screws (Figure 1). All impressions were taken with the same type and size of impression tray (Figure 1) to reduce impressions biases. Alginates were prepared with an automatic alginate mixing machine (Gulsa, Izmir, Turkey) (Figure 1) according to the manufacturers’ instructions.

| Materials |

Trade names -Manufacturers |

| Tray |

O-Tray - Dentaurum, Germany |

| Universal holder |

BM1 - Bosch, Germany |

| Alginate mixer |

AHTC.- MIX - Gulsa, Turkey |

| Gypsum |

Amerok - ADD, Turkey |

| Gypsum mixer |

Motova 100 - Bego, Germany |

| Microscope |

EZ4 HD - Lecia, Germany |

| 3D laser scanner |

NextEngine, USA |

| Alginates |

Hygemax, Hygedent, China |

| Hygemax Ext Pour Hygedent, China |

| Hydrogum, Zhermack, Germany |

| Hydrogum Ext Pour, Zhermack, Germany |

| Blueprint, Dentsply, United Kingdom |

| Cavex, Cavex Co., Holland |

| Disinfectants |

NaOCl

Izosprey, Biesterfeld Co., Germany

Zeta, Zhermack, Germany

Unident, USF Healthcare S.A., Switzerland |

Table 1 Materials used.

Figure 1 Materials used (Universal holder.

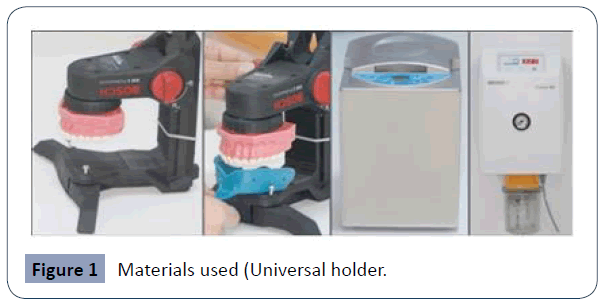

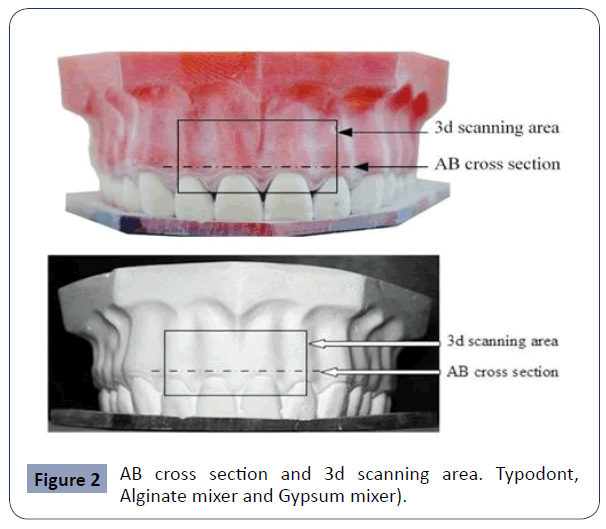

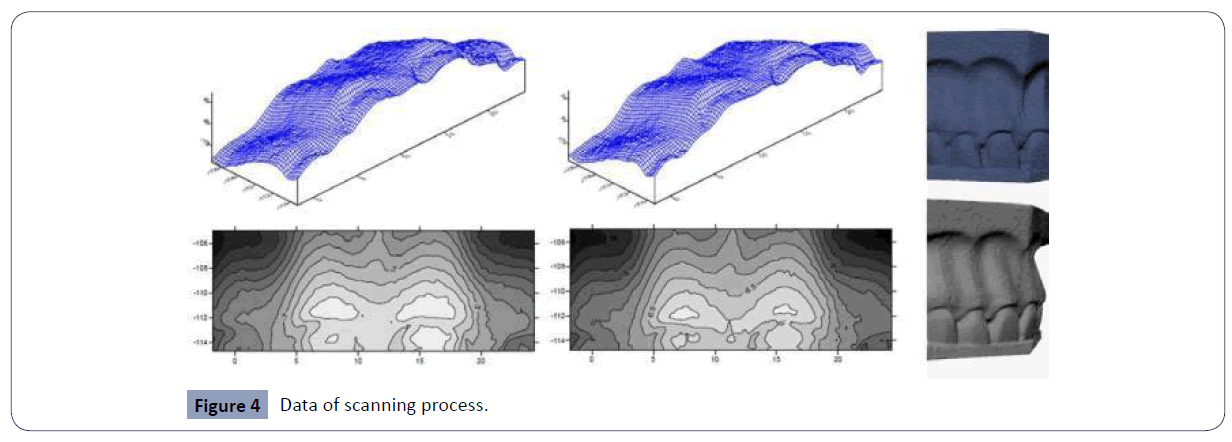

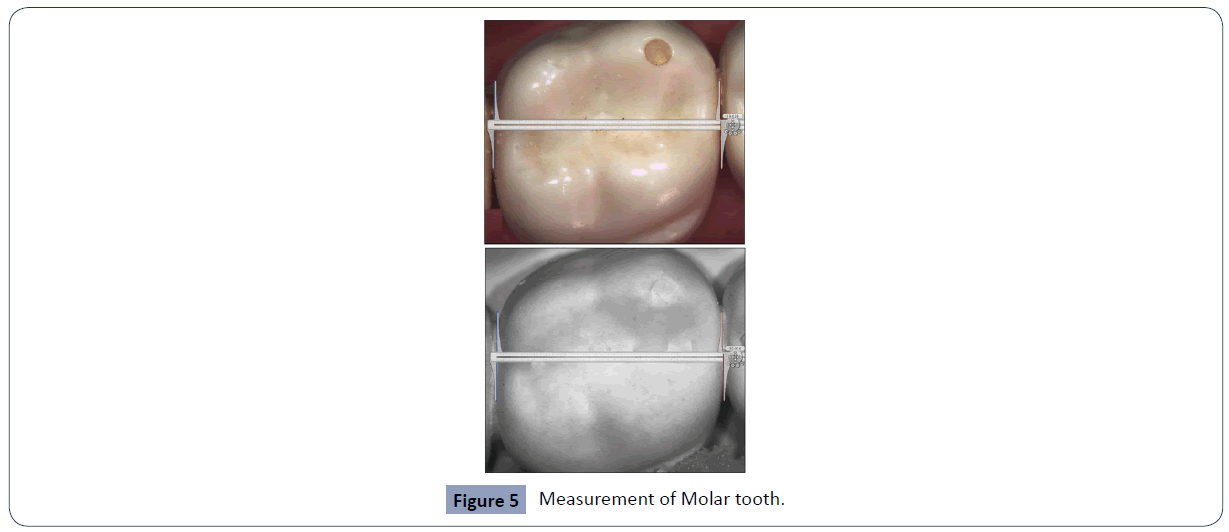

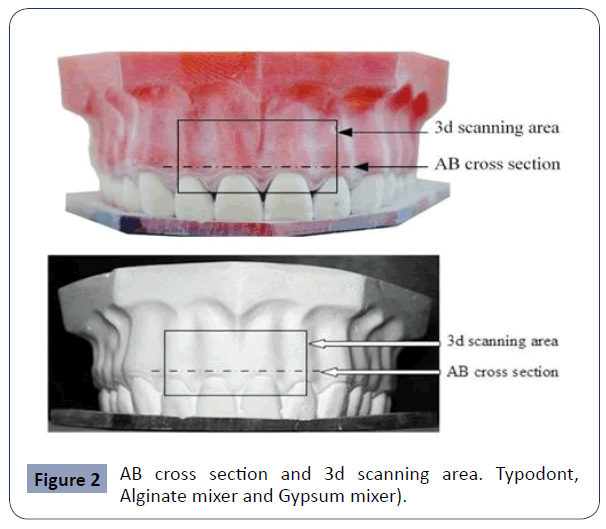

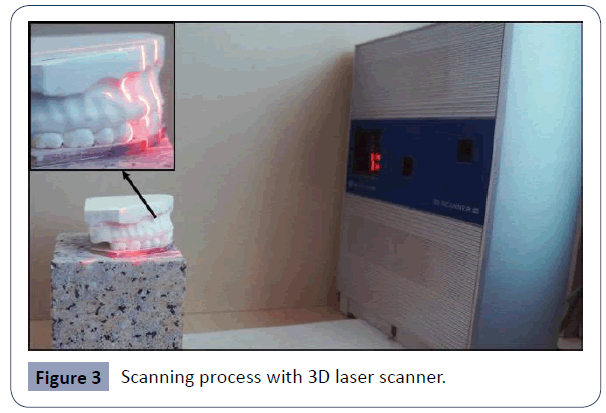

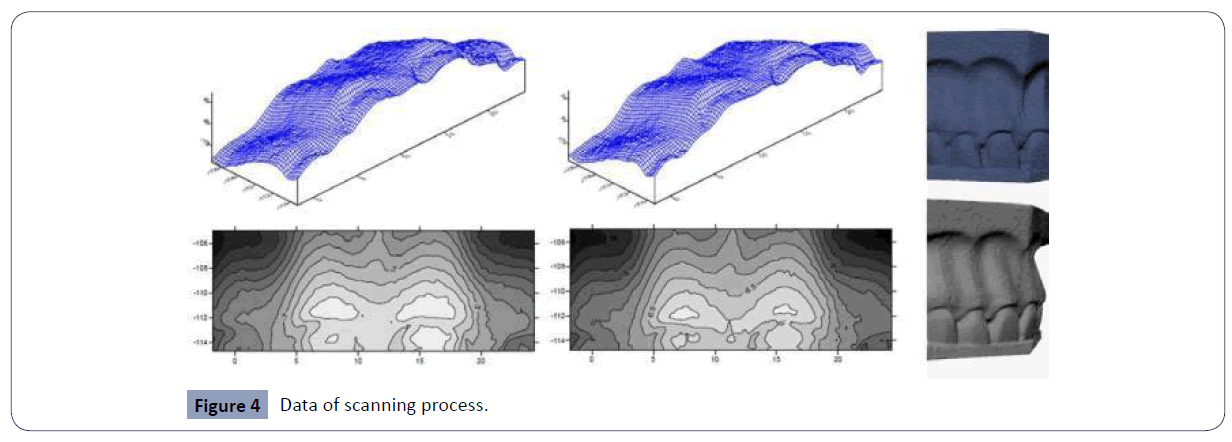

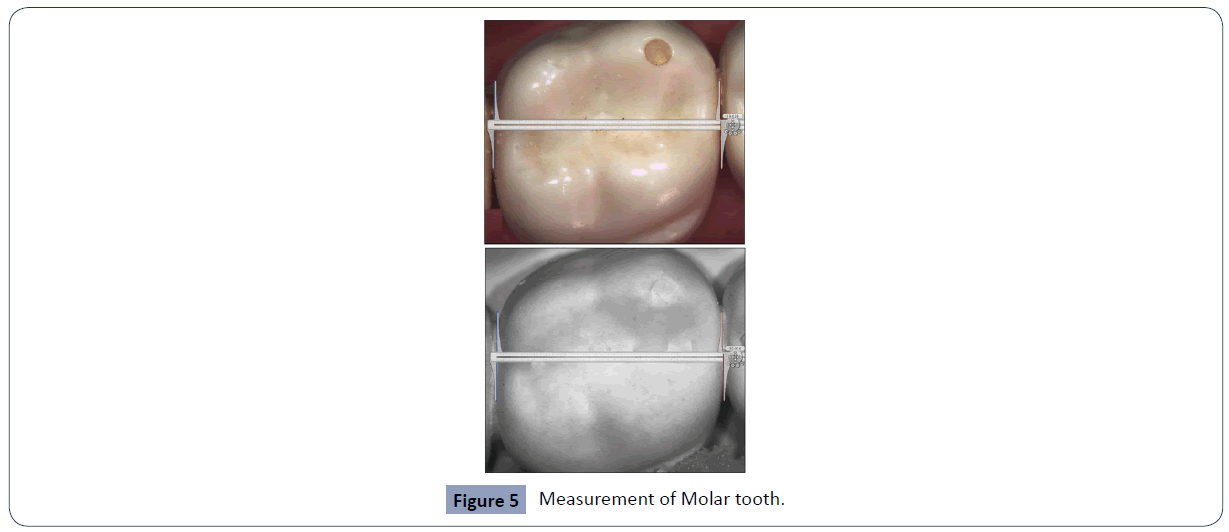

A total of 168 alginate impressions were taken and a disinfection process was applied according to manufacturers’ recommendations. One hundred and twelve of these impressions were poured immediately after the disinfection process, while the rest of the impressions were produced from an “extended pour.” Thesealginates were kept at room temperature in sealed plastic bags for four days and then poured. Pouring of impressions was standardized by using the same brand of gypsum as the control group and an automatic gypsum mixing machine (Bego, Bremen, Germany) (Figure 1). The stone models were divided into 24 groups and given numbers. Some reference points were determined and an experimental area was produced on the vestibule surface of the stone models (Figure 2). A splint was made for stabilization of the stone models during the scanning process (Figure 2). The splint and 3-D laser scanner (Next Engine Inc., Santa Monica, California, USA) were fixed together. Scanning the samples was carried out using the 3-D laser scanner’s (Figure 3) own software. The scanning area on the stone models that was set up (with the same reference coordinate) in the software was selected to provide the most favorable light contact for precise measurements during the scanning process. The resulting image from the scanner is a cloud of points with known positions (coordinates of x, y, z) on which the smallest possible triangles were drawn to create a dimensional approximation of the scanned surface with an approximation accuracy of 10 μm (Figure 4). The dimensional changes in the stone models were then calculated from the data generated by the AB cross- sectioning of the virtual stone models in the incisor region (Figure 2). Scanning the stone model samples, generating their virtual models, and gathering data (about 100 data points) from the cross-sections was carried out for each sample. At the same time, for each stone model, the right upper (Figure 4) molar size was measured with the help of a digital microscope (Leica Co., Mannheim, Germany) and screen caliper (Iconico software, California, USA) (Figure 5).

Figure 2 AB cross section and 3d scanning area. Typodont, Alginate mixer and Gypsum mixer).

Figure 3 Scanning process with 3D laser scanner.

Figure 4 Data of scanning process.

Figure 5 Measurement of Molar tooth.

In this study, cross-section data from the virtual 3-D model were used to analyze contractions in two dimensions with multiple data points while molar data were used in one dimension with one data point.Statistical analysis for dimensional changes was implemented by two-way analysis of variance (ANOVA) followed by Tukey’s post hoc test using R (2015) software. Tukey’s post hoc test was performed to compare mean values between groups. A value of p<0.05 was considered statistically significant.

Results

Table 2 illustrates the molar sizes and their contractions in cross tabulation form. These results indicate that molar contractionvaried between 1.2 and 3.2% in dimension. Table 3 shows the results of two-way ANOVA for molar measures. These results indicate that comparison of alginates was significant, but disinfectants and their interactions were not significant. A Tukey’s post hoc test revealed some significant results for alginate material pairs (Hydrogum–Hygemax Ext Pour, Hydrogum– Hydrogum Ext Pour, and Hydrogum Ext Pour–Blueprint), while results were nonsignificant for disinfectants and their interactions. According to the mean values of the stone models, the greatest contraction was realized on Hydrogum ExtPour alginate, which was also significantly different from the results of other alginates. The smallest contraction, on the other hand, was observed on Blueprint alginate. The contraction results for mean values of the stone models treated with disinfectant revealed that the greatest contraction was seen on NaOCl disinfectant and the smallest contraction was seen on Unident disinfectant, but the post hoc tests for this group showed insignificant results between disinfectants. It was also revealed that the best accuracy was obtained from Blueprint-Zeta, while the worst accuracy was obtained from the Hydrogum Ext Pour– NaOCl alginate– disinfectant combination.

| Alginate |

Disinfectant |

NaOCl |

Izosprey |

Zeta |

Unident |

Mean Contraction |

| |

mm |

(%) |

| HYGEMAX |

|

0.199

(0.046) |

0.171

0.073 |

0.252

(0.061) |

0.176

(0.093) |

0.2

(0.077) |

1.99 |

| HYGEMAX EXT POUR |

|

0.212

(0.039) |

0.215

(0.106) |

0.302

(0.069) |

0.185

(0.078) |

0.23

(0.084) |

2.28 |

| HYDROGUM |

|

0.174

(0.108) |

0.150

(0.091) |

0.177

(0.114) |

0.131

(0.016) |

0.158

(0.084) |

1.58 |

| HYDROGUM EXT POUR |

|

0.334

(0.130 |

0.215

(0.072) |

0.250

(0.044) |

0.313

(0.098) |

0.28

(0.107) |

2.77 |

| |

|

|

|

|

|

|

|

| BLUEPRINT |

|

0.195

(0.062) |

0.182

(0.071) |

0.124

(0.044) |

0.153

(0.095) |

0.156

(0.073) |

1.64 |

| |

|

|

|

|

|

|

|

| CAVEX |

|

0.192

(0.152) |

0.242

(0.049) |

0.142

(0.063) |

0.168

(0.105) |

0.19

(0.102) |

1.85 |

| Mean Contraction |

mm |

0.217

(0.106) |

0.196

(0.079) |

0.208

(0.094) |

0.188

(0.116) |

|

| (%) |

2.16 |

1.95 |

2.07 |

1.87 |

Table 2 Dental cast right upper first molar tooth size mean contraction and standard deviation-in parenthesis (mm, master typodont size: 10,028 mm).

| Sources |

Sum of Square |

D.F. |

Mean Square |

F (Pr) |

| Alginate (A) |

0.39 |

5 |

0.08 |

5.14 (0.00) |

| Disinfectant (B) |

0.04 |

3 |

0.01 |

0.94 (0.42) |

| A:B (interaction) |

0.33 |

15 |

0.02 |

1.47 (0.14) |

| Error (or residual) |

1.38 |

91 |

0.02 |

|

Table 3 Two-way ANOVA (with replication) results for molar tooth of stone models.

A more comprehensive analysis of dimensional change was carried out on 3-D scanner data from a cross-section of the incisor region (Table 4), as the data gathered from the molar size were limited to the number of stone models. The scanner data were statistically analyzed through two-way ANOVA with replication, and the differences between the means were calculated by Tukey’s honestly significant difference test with probability <0.05. The results are illustrated in Table 5. The data show that both factors (brand of alginate material and disinfectant material) as well as their interactions were significant, indicating substantial variation in the dimension of stonemodels.

| Alginate Disfectant |

NaOCl |

IZOSPREY |

ZETA |

UNIDENT |

Mean |

| HYGEMAX |

0.987

(0.149) |

1.454

(0.299) |

0.301

(0.122) |

0.33

(0.164) |

0.768

(0.478) |

| HYGEMAX EXT POUR |

0.29

(0.115) |

0.42

(0.113) |

0.508

(0.160) |

0.426

(0.121) |

0.411

(0.141) |

| HYDROGUM |

0.956

(0.191) |

0.496

(0.117) |

0.238

(0.100) |

0.042

(0.151) |

0.433

(0.275) |

| HYDROGUM EXT POUR |

0.16

(0.1090 |

0.377

(0.094) |

1.905

(0.262) |

0.305

(0.110) |

0.686

(0.670) |

| BLUEPRINT |

0.521

(0.194) |

0.737

(0.165) |

0.879

(0.124) |

0.059

(0.184) |

0.549

(0.241) |

| CAVEX |

0.255

(0.107) |

1.591

(0.398) |

0.291

(0.082) |

1.335

(0.285) |

0.868

(0.627) |

| Mean |

0.528

(0.304) |

0.845

(0.539) |

0.687

(0.575) |

0.416

(0.486) |

|

*Arithmetic mean and standard deviation (in parenthesis) of the difference between typodont and sample cross section.

Table 4 Cross tabulation of mean contraction of dental cast at cross section profile (mm)*.

| Sources |

Sum of Square |

D.F. |

Mean Square |

F (Pr) |

| Alginate (A) |

235 |

5 |

46.97 |

34.67 (0.00) |

| Disinfectant (B) |

246 |

3 |

81.88 |

60.44 (0.00) |

| A:B (interaction) |

1998 |

15 |

133.2 |

98.33 (0.00) |

| Error (or residual) |

14836 |

10959 |

1.35 |

|

Table 5 Two-way ANOVA (with replication) results for cross section of stone models’ incisor region.

A Tukey’s post hoc test revealed that the brand of alginate could be aggregated into three groups: Hygemax, Hydrogum Ext Pour, and Cavex; Hygemax Ext Pour and Hydrogum; and Blueprint. Pairwise comparisons within the aggregated groups were insignificant, while those among groups were significant. In the case of the disinfectant material, all pairwise comparisons showed significance differences. In addition, interactions between brand of alginate material and disinfectant were significant for many cases (Table 6). This study indicated that the contraction of stone models varies significantly depending on the alginate material and disinfectant used. Therefore, one should know the best combination for proper use. According to the results (with the investigated material), the best outcomes were obtained from Hydrogum and Blueprint alginate with Unident disinfectant. Yet, Hygemax Ext Pour alginate provided similar results for all disinfectants with the lowest mean value. The worst case in this experiment was obtained from Hydrogum Ext Pour alginate with Zeta disinfectant.

| Alginate – Disinfectant Material |

Alginate – Disinfectant Material |

Difference |

Prob |

| |

HYGEMAX - IZOSPREY |

-0.433 |

0.00 |

| HYGEMAX - NaOCl |

HYGEMAX - ZETA |

0.672 |

0.00 |

| |

HYGEMAX - UNIDENT |

0.637 |

0.00 |

| |

HYGEMAX EXT POUR - IZOSPREY |

-0.126 |

0.99 |

| HYGEMAX EXT POUR - NaOCl |

HYGEMAX EXT POUR - ZETA |

-0.223 |

0.31 |

| |

HYGEMAX EXT POUR - UNIDENT |

-0.137 |

0.98 |

| |

HYDROGUM - IZOSPREY |

0.457 |

0.00 |

| HYDROGUM - NaOCl |

HYDROGUM - ZETA |

0.721 |

0.00 |

| |

HYDROGUM - UNIDENT |

0.982 |

0.00 |

| |

HYDROGUM EXT POUR - IZOSPREY |

-0.234 |

0.22 |

| HYDROGUM EXT POUR - NaOCl |

HYDROGUM EXT POUR - ZETA |

-1.716 |

0.00 |

| |

HYDROGUM EXT POUR - UNIDENT |

-0.16 |

0.90 |

| |

BLUEPRINT - IZOSPREY |

-0.174 |

0.92 |

| |

BLUEPRINT - ZETA |

-0.31 |

0.02 |

| |

BLUEPRINT - UNIDENT |

0.474 |

0.00 |

| |

CAVEX - IZOSPREY |

-1.27 |

0.00 |

| |

CAVEX - ZETA |

-0.044 |

1.00 |

| |

CAVEX - UNIDENT |

-1.042 |

0.00 |

Table 6 Tukey’s some pairwise comparison results for interaction (A*B).

Discussion

In the present study, a maxillary typodont was used as a master model, in line with many previous studies. For the effects of the type of gypsum and mixing methods on model dimensions [13- 15]. All these study design factors led to the sound comparison of groups with one another. The scanning region on the stone models was selected to provide the most favorable light contact for precise measurements. The accuracy of the scanning process with the 3-D laser scanner was proper and sufficient for this experimental study. This surface analysis can help clinicians see what is really going on in terms of surface dimensions and can be helpful for laboratory work like removable appliance production or can simulate lingual retainer production. In addition, for comparability and percentage contraction calculations, measuring the right upper first molar size with the help of a digital microscope can provide an idea about a linear analysis of stone models like the Bolton analysis. The effects of different alginate impression materials and disinfectant solutions on the dimensional change and the dimensional stability of resultant stone models have been previously investigated, and different results have been obtained [16]. In the present study, it was indicated that the type of alginate material and disinfectant can effects the contraction of stone models significantly like some previous studies.

In literature, the study of disinfectant solutions (sodium hypochlorite and glutaraldehyde) on stone models from three brands of alginate impression materials (Algiace Z, Star Mix, and Alginoplast EM) with gypsum showed no significant differences regarding the dimensional change between the spray treatments of different disinfectant solutions, except for the Star Mix impressions [17]. Present study’s results show that the combination of alginate material and disinfectant very important for degree of contraction. Linear measurement of molar tooth width detected different degree of contraction between 1.2 and 3.2%. In the present study, different type of alginate materials and disinfectants were used. These factors and the disinfection method can affect the results of the study. On one hand the greatest contraction was realized on Hydrogum Ext Pour alginate, on the other hand the smallest contraction was observed on Blueprint alginate. Another study on stone models made by Hiraguchi et al [18]. It revealed that the dimensional stability of an alginate impression in sodium hypochlorite solution varied according to types and brands. It was also reported that alginate impression materials, similarly to another report on stone casts, showed small dimensional changes when immersed water or sodium hypochlorite solution [18,19]. However, Muzaffar et al [20] showed that Blueprint Cremix and Hydrogum alginates treated with distilled water, Perform ID and sodium hypochlorite over a period of 1 hour continuously shrank with time. Present studies results were analogous with these three studies’. Because detailed analysis of dimensional change was carried out on 3-D scanner data from a cross-section of the incisor region showed that the type of the disinfectant has significant effects on contraction. Present dimensional data gathered from this type of scanning method is new for dental dimensional researches and can be helpful at future studies. In addition, interactions between brand of alginate material and disinfectant were significant for some pair wise comparisons. The best combination was Hydrogum and Blueprint alginate with Unident disinfectant with lowest contraction. On the other hand, the worst combination was obtained from Hydrogum Ext Pour alginate with Zeta disinfectant with highest contraction.

As stated in previous studies, the dimensions of stone models produced from disinfectant-treated alginate impression materials demonstrate various degrees of contraction, emphasizing the need to observe alginate and disinfectant interactions for stone model dimensional accuracy.

Conclusion

The implication for the current work is clear: The dimensional accuracy of stone models varied with the alginate impression material and disinfectant solution used. Therefore, during clinical work one should work with the right combination of alginate and disinfectant solution and should follow manufacturing recommendations for proper use. According to this experiment, if Hydrogum or Blueprint alginate were planned for use in the process of stone modeling, then Unident disinfectant would be the accurate choice for good dimensional precision. In the case of Hygemax Ext Pour, all disinfectants would result in similar dimensional accuracy.

35523

References

- Goracci C, Franchi L, Vichi A, Ferrari M (2016) Accuracy, reliability, and efficiency of intraoral scanners for full-arch impressions: a systematic review of the clinical evidence. Eur J Orthod 38: 422-428.

- Coleman R M, Hembree J H, Weber F N (1979) Dimensional stability of irreversible hydrocolloid impression material. Am J Orthod Dentofacial Orthop 75: 438-446.

- Nassar U, Aziz T, Flores-Mir C (2011) Dimensional stability of irreversible hydrocolloid impression materials as a function of pouring time: a systematic review. J Prosthet Dent 106: 126-133.

- Zilberman O, Huggare J, Parikakis KA (2003) Evaluation of the validity of tooth size and arch width measurements using conventional and three-dimensional virtual orthodontic models. Angle Orthod 73: 301-306.

- Nandini VV, Venkatesh KV, Nair KC (2008) Alginate impressions: A practical perspective. J Conserv Dent 11: 37-41.

- Lippold C, Kirschneck C, Schreiber K, Abukiress S, Tahvildari A, et al. (2015) Methodological accuracy of digital and manual model analysis in orthodontics–A retrospective clinical study. Comput Biol Med 62: 103-109.

- Atabek D, Alaçam A, Tüzüner E, Polat S, Sipahi AB (2009) In- Vivo Evaluation of Impression Material Disinfection with Different Disinfectant Agents. Hacettepe Diş Hekimliği Fakültesi Dergisi 33: 52-59.

- Akca AE, Akca G, Sultan N, Özdemir A (2006) An in Vitro Evaluation of Various Disinfectants on Different Types of Contaminated Dental Materials. Hacettepe Diş Hekimliği Fakültesi Dergisi 30: 25-30.

- Kimondollo PM (1992) Guidelines for developing a dental laboratory infection-control protocol. Int J Prosthodont 5: 452-456.

- (1996) Infection control recommendations for the dental office and the dental laboratory. ADA Council on Scientific Affairs and ADA Council on Dental Practice. J Am Dent Assoc 127: 672-680.

- Khaledi A, Mahdavi F, Heidary H (2015) Dimensional Stability of Color-Changing Irreversible Hydrocolloids after Disinfection. J Dent Biomater 2: 29-32.

- Suprono MS, Kattadiyil MT, Goodacre CJ, Winer MS (2012) Effect of disinfection on irreversible hydrocolloid and alternative impression materials and the resultant gypsum casts. J Prosthet Dent 108: 250-258.

- Chang YC, Yu CH, Liang WM, Tu MG, Chen SY (2013) Comparison of the surface roughness of gypsum models constructed using various impression materials and gypsum products. J Dent Sci 11: 23-28.

- Dreesen K, Kellens A, Wevers M, Thilakarathne PJ, Willems G (2013) The influence of mixing methods and disinfectant on the physical properties of alginate impression materials. Eur J Orthod 35: 381-387.

- Wadhwa SS, Mehta R, Duggal N, Vasudeva K (2013) The effect of pouring time on the dimensional accuracy of casts made from different irreversible hydrocolloid impression materials. Contemp Clin Dent 4: 313-318.

- Todd JA, Oesterle LJ, Newman SM, Shellhart WC (2013) Dimensional changes of extended-pour alginate impression materials. Am J Orthod Dentofacial Orthop 143: 55-63.

- Hiraguchi H, Kaketani M, Hirose H, Yoneyama T (2010) The influence of storing alginate impressions sprayed with disinfectant on dimensional accuracy and deformation of maxillary edentulous stone models. Dent Mater J 29: 309-315.

- Hiraguchi H, Kaketani M, Hirose H, Yoneyama T (2012) Effect of immersion disinfection of alginate impressions in sodium hypochlorite solution on the dimensional changes of stone models. Dent Mater J 31: 280-286.

- Iwasaki Y, Hiraguchi H, Iwasaki E, Yoneyama T (2016) Effects of immersion disinfection of agar-alginate combined impressions on the surface properties of stone casts. Dent Mater J 35: 45-50.

- Muzaffar D, Ahsan SH, Afaq A (2011) Dimensional changes in alginate impression during immersion in a disinfectant solution. J Pak Med Assoc 61: 756-759.