Keywords

Tilapia; X-xylanase; Growth performance; Feed efficiency

Introduction

Tilapia (Oreochromis sp.) farming is a widespread industry in the world because of its high growth performance and market value, and it has become one of the most important aquaculture species in the world. The production of tilapia is increasing annually, and 5,576,800 metric tons were produced worldwide in 2015. As tilapia aquaculture has dramatically grown over the past decade, feed quality and utilization have become major issues standing in the way of the sustainable development of tilapia aquaculture.

Formulated diets are the primary food source used in tilapia aquaculture. Plant-derived proteins, such as soybean meal, rice gluten meal, rapeseed meal, rice gluten meal, and wheat middling’s, are widely used as ingredients in tilapia feed. However, the low nutrient utilization of plant-derived proteins by fish might result in lower growth performances and pollution of pond environment (Leenhouwer et al., 2007). The limited nutrient availability in aquafeed is mainly caused by non-starch polysaccharide (NSP) components (Sinha et al., 2011) and/or other anti-nutritional factors in plant-derived proteins (Cheng et al., 2013). Therefore, issues of anti-nutritional factors in plant-derived proteins must be dealt with to improve nutrient utilization and animal growth to bring down consequent costs of aquafeed.

Microbial enzymes are widely used in feed to minimize the problem of anti-nutritional factors, thereby improving the nutritive value (Forster et al., 1999), nutrient utilization (Cheng and Hardy, 2003; Cheng et al., 2013), animal growth (Sajjadi and Carter, 2004; Cheng et al., 2013; Saputra et al., 2016), and so on. Xylanases are a class of enzymes that degrade linear polysaccharides in plant cell walls into xylose, thus breaking down hemicellulose. They are found in numerous bacteria, yeasts, and fungi and play a role in those organisms' ability to thrive on plant sources by degrading plant matter into usable nutrition. Because of xylanase's capability of enzymatic digestion, it is considered a potential candidate for improving the efficiency of feed utilization and degrading NSPs of plant ingredients in animal feed. Xylanase has been widely used in the poultry (Yang et al., 2008; Pirgozliev et al., 2015) and livestock (Prandini et al., 2014; Passos et al., 2015) industries to enhance energy and nutrient availability of plant ingredients, but little is known about its application in aquaculture. Xylanase-producing yeasts were found in some freshwater fish species, such as Indian major carp (Cirrhinus mrigala) and Nile tilapia (Oreochromis niloticus), and xylanases released from yeast strains are thus available in the gut of fish and might promote NSP digestibility and utilization by fish (Gatesoupe, 2007; Banerjee and Ghosh, 2014). Purified xylanase was used in a plant protein-enriched diet of Jian carp (Cyprinus carpio var. Jian), which resulted in improvements in growth, in intestinal enzyme activities, and the microflora (Jiang et al., 2014); similar results were also recorded in Japanese seabass (Lateolabrax japonicas) (Ai et al., 2007).

It is well known that xylanases have great potential, as they are widely applied in the feed of terrestrial animals (Prandini et al., 2014; Passos et al., 2015). However, little is known about their application in aquaculture. Therefore, the efficiency of an X-xylanase product in improving feed utilization was evaluated by tracking the growth performance of red tilapia (Oreochromis sp.) in this study.

Materials and Methods

Experimental fish

Red tilapia for this experiment were bought from a private farm in Pingtung, Taiwan and then transported to the farm at the Department of Aquaculture, National Pingtung University of Science and Technology. Before the experiment, fish were reared in an outdoor 10-ton cement tank with continuous water flow, and fed by a control diet (Table 1) twice daily at around 10% of their body weight. The average weight of fish used was 0.43 ± 0.01 g at the beginning of the experiment.

| Ingredient |

Experimental diets (g/kg) |

| Commercial diet |

Control |

1050 EPU |

1500 EPU |

1950 EPU |

| Soybean meal |

|

350 |

350 |

350 |

350 |

| Fish meal |

|

50 |

50 |

50 |

50 |

| Corn starch |

|

50 |

50 |

50 |

50 |

| Wheat middlings |

|

129.675 |

129.675 |

129.675 |

129.675 |

| Rice bran |

|

250 |

250 |

250 |

250 |

| α-starch |

|

100 |

100 |

100 |

100 |

| Soybean oil |

|

10 |

10 |

10 |

10 |

| Xylanase (X 6000) |

|

0 |

0.175 |

0.25 |

0.325 |

| Inactive-xylanase (X 6000) |

|

0.325 |

0.15 |

0.075 |

0 |

| Mineral premix |

|

30 |

30 |

30 |

30 |

| Vitamin premix |

|

30 |

30 |

30 |

30 |

| Chemical analysis (%) |

|

|

|

|

|

| Moisture |

6.33 |

2.54 |

2.34 |

2.87 |

2.5 |

| Crude protein |

23.92 |

24.31 |

24.56 |

24.48 |

24.31 |

| Crude lipids |

8.03 |

8.68 |

9.12 |

8.24 |

9.01 |

| Ash |

7.8 |

9.2 |

9.1 |

9.05 |

8.85 |

Note: EPU-Endopentosanase units.

Table 1: Ingredients of experimental diets used in the study.

Preparation of the experimental diets

Table 1 shows ingredients of the experimental diets. Four experimental diets were formulated to contain graded levels of X-xylanase (0 (control), 1050, 1500, and 1950 endopentosanase units (EPU)) using Hostazym® X-xylanase (X 6000, Huvepharma, Antwerp, Belgium). X-xylanase was added to the experimental diets with a corresponding decrease in the amount of inactivexylanase. Ingredients were ground in a Hammer mill until they passed through a 60-mesh screen. The experimental diets were prepared by mixing the dry ingredients with soybean oil and then adding water until a stiff dough resulted. Each diet was then passed through a mincer with a die, and the resulting spaghetti-like strings were dried to a moisture level of 10% in a drying cabinet at 50°C with an air blower. After drying, the pellets were stored in plastic bins at -4°C until being used. Proximate analysis of the experimental and commercial diet (moisture, crude protein, crude lipid and ash) was performed according to AOAC procedures (1984).

Growth performance trial

A 56-day growth performance trial was conducted in 2-ton cement tanks with continuous water flow and aeration to maintain suitable water quality and dissolved oxygen (DO) of ≥ 5 mg/L. Tilapia juveniles were randomly assigned to four groups, and tests were carried out in triplicate. Each replicate consisted of 50 fish. In addition, a group of fish fed a commercial diet was used as control. Fish were fed twice daily at a ratio of 10% of their body weight at 08:00 and 15:00. Any uneaten feed was collected 1 h after feeding, and then immediately dried in an oven at 80°C. The amount of all diets consumed was calculated by subtracting the uneaten feed and was recorded on a daily basis. The weight of fish was measured at the start of the experiment and at 2-week intervals until the end of the experiment. Water temperature, dissolved oxygen (DO), and pH were respectively determined daily using a thermometer, DO meter, pH meter. Ammonia-N (Solorzano, 1969) and nitrite-N (Bendschreider and Robinson (1952) were measured every 2 weeks during the growing-out phase. At the end of the experiment fish were individually weighted. Condition factor, survival rate, weight gain and feed efficiency were determined using following equations:

Condition factor=body weight/(body length)3 × 100%,

Survival rate (%)=(final number of tilapia/initial number of tilapia) × 100%,

Percentage weight gain (%)=[(final weight - initial weight)/ initial weight] × 100%, and Feed efficiency=weight gain/total feed intake.

The cost per kg fish production (NT$) was calculated as following formula: Cost per kg fish production=(Feed cost per kg × total feed intake (kg))/ weight gain (kg).

Whole-body composition analysis

After the experiment, six fish from each treatment were selected for a whole-body composition analysis. All fish samples were analyzed in duplicate for proximate composition following the standard methods (AOAC, 1984). Moisture was determined by a moisture analyzer (MX-50, A & DJapan). Crude protein was measured by the Kjeldahl procedure using the Kjeltec System (Tecator, Sweden) after acid digestion. Crude lipids were analyzed by the method of Folch et al., 1957. Ash was determined after burning at 550oC in a muffle furnace.

Statistical Analysis

Experimental data were statistically analyzed by a one-way analysis of variance (ANOVA) and Duncan’s multiple-range test in SAS software (Cary, NC, USA) to determine variations and the significance of differences between treatments. All percentage data were square-root arcsine-transformed before the statistical analysis. The level of significance was accepted at p<0.05.

Results and Discussion

Proximate analysis of the experimental diets

Proximate analysis of the experimental diets showed no significant differences in the moisture (2.34%-2.50%), ash (8.85%-9.2%), crude protein (24.31%-24.56%), or crude lipid (8.24%-9.12%) levels among all experimental diets. Compared to the proximate analysis of the commercial diet (crude protein 23.92%, moisture 6.33%, crude lipids 8.03% and ash 7.8%), the experimental diets seemed to have similar nutrient values, which should not have influenced the growth performance of tilapia compared to fish fed the commercial diet.

Growth performance

During the experiment, the water quality did not significantly differ among the treatments. The water temperature ranged 25- 26.3°C, pH 7.3-8.3, DO >5 mg/L, ammonia-N 0.002-0.22 mg/L, and nitrite-N 0.013-0.23 mg/L.

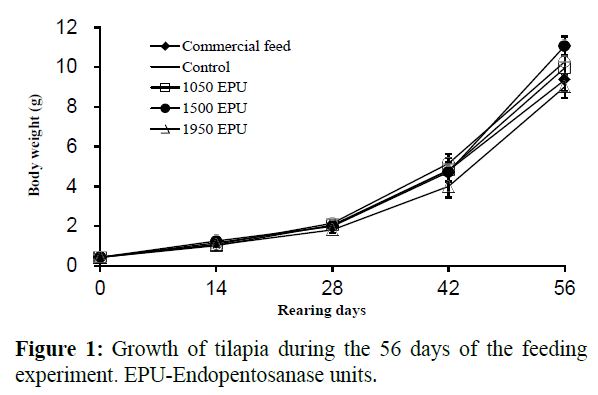

Figure 1 shows the growth performance of tilapia fed the different experimental diets for 56 days. Growth performance results indicated that no significant difference was seen in the growth of tilapia fed the experimental diets and commercial diet, which may have been caused by individual growth differences among fish. However, fish fed the diet containing X-xylanase at a level of 1500 EPU seemed to have the highest weight compared to those of fish fed the other experimental diets and the commercial diet, but the growth rate of tilapia was reduced when an excessive dose of X-xylanase in the diet was offered to fish for 56 days in this study (Figure 1). Fish fed xylanase-supplemented diets having better growth performances was also found in juvenile Jian carp (Jiang et al., 2014) and Japanese seabass (Ai et al., 2007). In addition, animals with poor weight gain after consuming a diet with an excessive amount of supplemented xylanase were also recorded in Jian carp (Jiang et al., 2014) and broilers (Mendoes et al., 2013), which might have been due to the overproduction of xylooligosaccharides and xylose (Schutte, 1999; Xu et al., 2009).

Figure 1: Growth of tilapia during the 56 days of the feeding experiment. EPU-Endopentosanase units.

Xylanase applied in animal feed to improve feed utilization was reviewed (Goswami and Pathak, 2013), and previous studies showed that xylanase was able to improve the growth performance and feed utilization in poultry and pigs (Goswami and Pathak, 2013; Woyengo et al., 2013). In aquaculture, a case of using multiple exogenous enzymes (including xylanase) in the diet of African catfish (Clarias gariepinus) resulted in enhanced fish growth performance and feed utilization (Yildirim and Turan, 2010). In Nile tilapia, fish fed a diet containing the xylanase-expressing probiotic, Bacillus amyloliquefaciens R8, which expresses the xylanase gene from rumen fungi, also had a significantly better growth performance and health status compared to fish fed a control diet or wild B. amyloliquefaciens (Saputra et al., 2016). Similarity, X-xylanase incorporated in the diet at a level of 1500 EPU was able to improve the feed efficiency, a good indicator for evaluating feed quality (Table 2). The improved feed efficiency of fish fed the X-xylanase-supplemented diet at a level of 150 EPU indicated that the product really would be beneficial to tilapia aquaculture by improving feed utilization. At the end of the experiment, mean weights of fish in the commercial diet, control, 1050 EPU, 1500 EPU, and 1950 EPU groups were 9.36, 10.27 ± 0.7, 9.96 ± 1.15, 11.07 ± 0.48, and 9.01 ± 0.57 g, respectively (Table 2).

| |

Experimental diets |

| Commercial feed |

Control |

1050 EPU |

1500 EPU |

1950 EPU |

| Initial weight (g) |

0.43 ± 0.01 |

0.43 ± 0.01 |

0.43 ± 0.01 |

0.43 ± 0.01 |

0.43 ± 0.01 |

| Final weight (g) |

9.36 |

10.27 ± 0.7 |

9.96 ± 1.15 |

11.07 ± 0.48 |

9.01 ± 0.57 |

| Condition factor |

2.08 |

2.27 ± 0.03 |

2.25 ± 0.08 |

1.90 ± 0.30 |

2.12 ± 0.06 |

| Survival (%) |

98 |

100 |

96.67 ± 2.40 |

97.33 ± 1.76 |

98.67 ± 0.67 |

| Feed efficiency |

0.68c |

0.71 ± 0.01bc |

0.72 ± 0.03bc |

0.81 ± 0.01a |

0.76 ± 0.02b |

| Percentage weight gain (%) |

2076.08 |

2289.77 ± 162.46 |

2215.95 ± 266.47 |

2474.31 ± 110.35 |

1996.20 ± 133.19 |

Note: EPU- Endopentosanase units.

Table 2: Initial weight, final weight, condition factor, survival, feed efficiency, and percentage weight gain of red tilapia fed by commercial, control and experimental diets. (Data ± standard error; different letters among treatments indicate a significant difference, p<0.05).

This study found no significant difference in the body composition of red tilapia, including moisture, protein, lipid, and ash contents among fish fed the commercial, control, and experimental diets. However, fish fed X-xylanase-supplemented diets seemed to have higher protein contents compared to the control and commercial diet groups (Table 3), and the increased tendency of protein content in the fish body was similar to the increase in feed efficiency which was highest at the optimal level (1500 EPU) of xylanase in the diet, and then decreased in the group supplemented with an excessive amount (1950 EPU) of X-xylanase in the diet. Net nutrient retention is considered an accurate and important indicator for evaluating the feed efficiency in fish (Belal, 2005). Results of increased body protein contents and feed efficiency in red tilapia fed X-xylanase-supplemented diets agree with results of Jiang et al. (2014). Furthermore, data on the body composition of tilapia in this study were similar to those of tilapia in a previous study (Gao et al., 2015).

| Experimental diets |

Whole body composition (%) |

| Moisture |

Protein |

Lipids |

Ash |

| Commercial feed |

71.12 ± 2.22 |

17.28 ± 0.83 |

8.24 ± 0.83 |

4.72 ± 0.81 |

| Control |

70.28 ± 1.38 |

17.25 ± 0.63 |

8.32 ± 0.71 |

4.93 ± 0.25 |

| 1050 EPU |

70.88 ± 2.27 |

18.02 ± 1.40 |

7.92 ± 0.683 |

4.88 ± 0.66 |

| 1500 EPU |

71.25 ± 2.11 |

18.62 ± 0.86 |

7.81 ± 0.61 |

5.21 ± 0.91 |

| 1950 EPU |

70.68 ± 2.47 |

17.92 ± 0.76 |

8.76 ± 0.66 |

5.08 ± 0.35 |

Note: EPU- Endopentosanase units.

Table 3: Effects of different diets on the body composition of red tilapia.

Cost analysis

The cost of the experimental diet was estimated to be NT $31.38/kg. (The average exchange rate is US $1≈New Taiwan (NT) $30) (Table 4). No difference in the cost was calculated among the experimental diets because the inactive enzyme was added with a corresponding decrease in the amount of X-xylanase (the cost of X-xylanase was NT $600 /kg). The cost of feed for 1 kg of tilapia production in the control, and 1050, 1500, and 1950 EPU groups were NT $44.46 ± 0.30, NT $43.68 ± 2.07, NT $38.78 ± 0.46, and NT $41.62 ± 1.06, respectively. Therefore, producing 1 kg of tilapia using the X-xylanase-supplemented diets at the levels of 1050, 1500, and 1950 EPU could save NT $0.78, NT $5.68, and NT $2.84, respectively, compared to the control. It was thus concluded that using X-xylanase in the diet for tilapia aquaculture would be profitable, and the recommended level is 1500 EPU.

| Diets |

Cost |

Total feed intake |

Weight gain |

Cost of 1 kg of fish production |

| (NT$) |

(kg/fish) |

(kg/replicate) |

(NT$) |

| Control |

31.38 |

0.698 ± 0.061 |

0.492 ± 0.043 |

44.46 ± 0.30 |

| 1050 EPU |

31.38 |

0.658 ± 0.075 |

0.476 ± 0.070 |

43.68 ± 2.07 |

| 1500 EPU |

31.38 |

0.658 ± 0.039 |

0.531 ± 0.029 |

38.78 ± 0.46 |

| 1950 EPU |

31.38 |

0.571 ± 0.059 |

0.429 ± 0.035 |

41.62 ± 1.06 |

Note: EPU-Endopentosanase units. The average exchange rate is US$1≈New Taiwan (NT)$30.

Table 4: Cost analysis of the diets used in this study.

Conclusion

The present study clearly shows that X-xylanase is a great exogenous enzyme to improve feed utilization and consequently improve the fish growth performance when added to the diet at a level of 1500 EPU. It is therefore suggested that X-xylanase be used in the diet to improve the feed efficiency and tilapia growth performance at a level of 1500 EPU.

Acknowledgements

This study was supported by a grant (MOST 104-2313-B-020- 006-MY3) from the Ministry of Science and Technology, ROC, and Huvepharma Taiwan (Brach of Huvepharma NV).

22209

References

- Ai, Q., Mai, K., Zhang, W., Xu, W., Tan, B., et al. (2007) Effects of exogenous enzymes (phytase, non-starch polysaccharide enzyme) in diets on growth, feed utilization, nitrogen and phosphorus excretion of Japanese seabass, Lateolabrax japonicas. Comparative Biochemistry and Physiology Part A: Mol Integrative Physiol 147, 502-508.

- AOAC (1984) Official Methods of Analysis of the Association of Official Analytical Chemists, 14th ed. Association of Official Analytical Chemists, Arlington, V.A.

- Banerjee, S., Ghosh, K. (2014) Enumeration of gut associated extracellular enzyme-producing yeasts in some freshwater fishes. J Applied Ichthyol 30, 986-993.

- Belal, I.E.H. (2005) A review of some fish nutrition methodologies. Bioresource Technol 96, 395-402.

- Bendschneider, D.A., Robinson, R.J. (1952) A new spectrometric method for the determination of nitrite in the sea water. J Marine Res 11, 87-96.

- Cheng, Z.J., Hardy, R.W. (2003) Effects of extrusion and expelling processing, and microbial phytase supplementation on apparent digestibility coefficients of nutrients in full-fat soybeans for rainbow trout (Oncorhynchus mykiss). Aquacult 218, 501-514.

- Cheng, W., Chiu, C.S., Guu, Y.K., Tsai, S.T., Liu, C.H. (2013) Expression of recombinant phytase of Bacillus subtilis E20 in Escherichia coli HMS 174 and improving the growth performance of white shrimp, Litopenaeus vannamei, juveniles by using phytase-pretreated soybean meal-containing diet. Aquaculture Nutrition 19, 117-127.

- Folch, J., Lees, M., Sloane-Stanley, C.H. (1957) A simple method for the isolation and purification of total lipids from animal tissue. J Biol Chem 226, 497-509.

- Forster, I., Higgs, D.A., Dosanjh, B.S., Rowshandeli, M., Parr, J. (1999) Potential for dietary phytase to improve the nutritive value of canola protein concentrate and decrease phosphorus output in rainbow trout (Oncorhynchus mykiss) held in 11°C fresh water. Aquacult 179, 109-125.

- Gao, Y., Wang, Z., Hur, J.W., Lee, J.Y. (2015) Body composition and compensatory growth in Nile tilapia Oreochromis niloticus under different feeding intervals. Chinese J Oceanology Limnol 33, 945-956.

- Gatesoupe, F.J. (2007) Live yeast in the gut: Natural occurrence, dietary introduction, and their effects on fish health and development. Aquacult 267, 20-30.

- Goswami, G. K., Pathak, RR. (2013) Microbial xylanase and their biomedical applications: a review. International J Basic Clinical Pharmacol 2, 237-246.

- Jian, T.T., Feng, L., Liu, Y., Jiang, W.D., Jiang, J., et al. (2014) Effects of exogenous xylanase supplementation in plant protein-enriched diets on growth performance, intestinal enzyme activities and microflora of juvenile Jian carp (Cyprinus carpio var. Jian). Aquacult Nutrition 20, 632-645.

- Leenhouwers, J.I., ter Veld, M., Verreth J.A.J., Schrama, J.W. (2007) Digesta characteristics and in relation to nutrient digestibility and mineral absorption in Nile tilapia (Oreochromis niloticus L.) fed cereal grains of increasing viscosity. Aquacult 273, 556-565.

- Mendes, A.R., Ribeiro, T., Correia, B.A., Bule, P., Maçãs, B., et al. (2013) Low doses of exogenous sylanase improve the nutritive value of triticale-based diets for broilers. Journal of Applied Poultry Research 22, 92-99.

- Passos, A.A., Andrade, C., Phillips, C.E., Coffey, M.T., Kim, S.W. (2015) Nutrient value of spray field forages fed to pigs and the use of feed enzymes to enhance nutrient digestibility. J Animal Sci 93, 1721-1728.

- Pirgozliev, V., Rose, S.P., Pellny, T., Amerah, A.M., Wickramasinghe, M. et al. (2015) Energy utilization and growth performance of chickens fed novel wheat inbred lines selected for different pentosane levels with and without xylanase supplementation. Poultry Sci 94, 232-239.

- Prandini, A., Sigolo, S., Morlacchini, M., Giuberti, G., Moschini, M., et al. (2014) Addition of nonstarch polysaccharides degrading enzymes to two hulless barley varieties fed in diets for weaned pigs. J Animal Sci 92, 2080-2086.

- Sajjadi, M., Carter, C.G. (2004) Dietary phytase supplementation and the utilization of phosphorus by Atlantic salmon (Salmo salar L.) fed a canola-meal-based diet. Aquacult 240, 417-431.

- Saputra, F., Shiu, Y.L., Chen, Y.C., Puspitasari, A.W., Danata, R.H., et al. (2016) Dietary supplementation with xylanase-expressing B. amyloliquefaciens R8 improves growth performance and enhances immunity against Aeromonas hydrophila in Nile tilapia (Oreochromis niloticus). Fish Shellfish Immunol 58, 397-405.

- Schutte, J.B. (1990) Nutritional implications and metabolizable energy value of D-xylose and L-arabinose in chicks. Poultry Sci 69, 1724-1730.

- Sinha, A.K., Kumar, V., Makkar, H.P.S., De Boeck, G., Becker, K. (2011) Non-starch polysaccharides and their role in fish nutrition – a review. Food Chem 127, 1409-1426.

- Solorzano, L. (1969) Determination of ammonia in natural water by the phenolpochlorite method. Limnol Oceanography 14, 799-801.

- Woyengo, T.A., Sands, J.S., Guenter, W., Nyachoti, C.M. (2013) Nutrient digestibility and performance responses of growing pigs fed phytase- and xylanase-supplemented wheat-based diets. J Animal Sci 86, 848-857.

- Xu, B., Wangm Y., Li, J., Lin, W. (2009) Effect of prebiotic xylooligosacharides on growth performances and digestive enzyme activities of allogynogenetic crucian carp (Carassius auratus gibelion). Fish Physiol Biochem 35, 351-357.

- Yang, Y., Iji, P.A., Kocher, A., Mikkelsen, L.L., Choct, M. (2008) Effects of xylanase on growth and gut development of broiler chickens given a wheat-based diet. Asian-Australian J Animal 21, 1659-1664.

- Yildirim, Y.B., Turan, F. (2010) Effects of exogenous enzyme supplementation in diets on growth and feed utilization in African catfish, Clarias gariepinus. J Animal Veterinary Advance 9, 327-331.