Research Article - (2024) Volume 16, Issue 2

Formulation of baclofen microemulsion and validation of analytical method for quantitative estimation by UV spectroscopy

Patidar Mohini*,

Pillai Sujit,

Deshmukh Nitin,

Patel Sumit and

Mahajan Aakansha

Department of Pharmaceutical analytical Science, GRY Institute of Pharmacy, Borawan, India

*Correspondence:

Patidar Mohini, Department of Pharmaceutical analytical Science, GRY Institute of Pharmacy, Borawan,

India,

Email:

Received: 14-Jun-2023, Manuscript No. IJDDR-23-13889;

Editor assigned: 17-Jun-2023, Pre QC No. IJDDR-23-13889 (PQ);

Reviewed: 02-Jul-2023, QC No. IJDDR-23-13889;

Revised: 05-Mar-2024, Manuscript No. IJDDR-23-13889 (R);

Published:

12-Mar-2024

Abstract

Baclofen is a centrally acting skeletal muscle relaxant used to treat muscle spasticity and multiple sclerosis. Baclofen hydrophilic characteristics make it challenging for it to cross the blood brain barrier, resulting in a bioavailability of less than 60%. The current study's objectives are to develop, optimize and validate an analytical method for the quantitative estimation of Baclofen by UV-visible spectrophotometer in accordance with ICH guidelines, as well as to improve the bioavailability and efficacy of drug release by formulating micro emulsion of Baclofen. Four different batches were formulated on the bases of S/Cos ratios 3:1, 3.5:1, 4.5:1 and 1.5:1 respectively by water titration method. Tween 80, span 80 and PEG 400 were blended together to form a homogeneous mixture, Baclofen was dissolved in oil phase. Oil phase and surfactant mixture were mixed slowly with continuous trituration. Drop wise additions of water were made to the existing mixture, which was stirred for 30 minutes at 3000 rpm on a magnetic stirrer. The result of FTIR study were indicated compatibility in between Baclofen and excipients. On the bases of solubility studies 0.1 N NaOH was selected for analytical method validation. The ƛmax and regression equation found to be 221 nm and Y=0.0603x+0.0207, R2=0.999. The result of all analytical validation parameters was not exceeding by 2% RSD value. Out of all batches M1 shows more transparent, no phase separation, pH of 6.7, particle size 100 nm, low viscosity and 96.73% drug content value. It exhibited good stability over the course of the six month stability tests, with no significant changes in its physicochemical characteristics. Hence, it was concluded that the micro emulsion formulation of Baclofen is a potential method for oral delivery that will increase bioavailability.

Keywords

Baclofen; Micro emulsion; Analytical method; 0.1 NaOH; Tween 80;

Castor oil; Polyethylene glycol

Abbreviations

NDDS: Novel Drug Delivery System; FTIR: Fourier Transform

Infrared analysis; UV spectroscopy: Ultra Violet spectroscopy; LOD: Limit of

Detection; LOQ: Limit of Quantitation; SD: Standard Deviation; RSD: Relative

Standard Deviation of the Response; σ: Slope of the calibration curve; PEG:

Polyethylene Glycol

Introduction

The term NDDS refers to entirely novel, innovative approaches for

effectively delivering pharmaceutical compounds inside the body

as needed to achieve their desired beneficial effects. Site targeting

within the body might be a part of it. It frequently worries about

both the quantity and frequency of consumption of drugs. Drug

delivery is a term that directly pertains to dosage and administration

method. The goal of NDDS is to specifically target a medication

to the necessary tissue while also improving medication potency,

controlling medication release to ensure a continued beneficial

impact and providing higher safety [1].

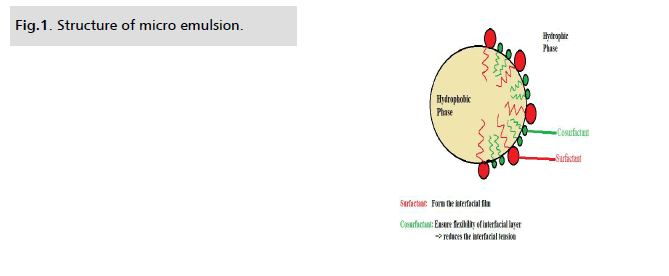

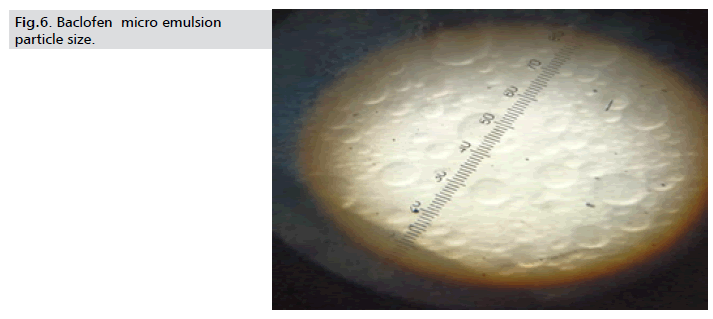

A micro emulsion was first proposed by Hoar and Schulman in

1943. A type of NDDS technological advances is micro emulsion

[2]. Micro emulsions are liquid combinations of oil, water and a

surfactant that are transparent, stable and isotropic, typically in

combination with another surfactant called a co-surfactant. The

"oil" may actually be a complex blend of various hydrocarbons

and olefins, while the aqueous phase may also contain salt(s) and/

or other substances. Micro emulsions do not require the high

shear conditions that are often employed to create conventional

emulsions, in contrast to ordinary emulsions and they develop

simply by mixing the components. Oil distributed in water is known

as a direct micro emulsion and water dispersed in oil is known as

a reverse micro emulsion. When two immiscible phases (water and

"oil") are present with a surfactant in ternary systems like micro

emulsions, the surfactant molecules may form a monolayer at the

interface between the oil and water. Small droplets or particles in

the dispersed phase typically range in size from 10 to 200 nm [3,4].

Classification of micro emulsion

Winsor identified four different types of micro emulsion phases

that are present in equilibrium and are referred to as Winsor phases.

Winsor I (two phase system): Upper oil layer and lower (o/w)

micro emulsion phase are in equilibrium.

Winsor II (two phase system): The upper (w/o) micro emulsion

and lower surplus water are in equilibrium

Winsor III (three phase system): Middle bi-continuous phase of

o/w and w/o, also known, is in equilibrium with upper phase oil

and lower phase water.

Winsor IV (single phase system): It creates a uniform mixture of

oil, water and surfactant [5].

Micro emulsions are superior to traditional emulsions, suspensions

and micelles solutions as well as the colloidal systems under

examination and they may provide other carriers. They are

promising delivery methods that enable prolonged or controlled

release for the administration of medications via percutaneous,

oral, topical, transdermal, visual and parenteral routes. They

benefit from spontaneous synthesis, simplicity in manufacturing

and scalability, thermodynamic stability, increased hydrophobic

drug solubilisation in medications and bioavailability [6].

Baclofen (γ-amino-β-[p-chlorophenyl]-butyric acid) is a centrally

acting skeletal muscle relaxant derived from the inhibitory

neurotransmitter γ-Amino Butyric Acid (GABA). It is used to treat

muscle spasticity, especially in patients with multiple sclerosis or

with spinal or cerebral disorders [7].

Baclofen has hydrophilic properties and does not readily cross the

blood brain barrier, because of this it’s has less than 60% oral bio

availability. The half-life is 2-6 hours after oral administration.

70%-80% of Baclofen is eliminated in an unchanged form by renal

excretion. Drug concentrations of Baclofen in the cerebrospinal

fluid are approximately 8.5 times lower than in the plasma due to

this it is prescribed to take TDS. In market Baclofen is available in

tablet, solution, packet and suspension formulations [8].

In this study, a Baclofen o/w micro emulsion was created using

polymer, oil and surfactant to increase bioavailability and improve

drug absorption across biological membranes. Low viscosity micro

emulsions have greater absorption into the body, less surfactant

content decreases negative effects and prevent first pass metabolism

which increases the bioavailability of the drug. As a less cost, more

easily scaled up option to the traditional oral, micro emulsion

formulation can be formulated.

A number of analytical methods were available to assess the purity

of the drug Baclofen through UV spectroscopy by using different

solvents. Another goal of this study to develop and optimize a

new analytical method which is quick, simple, precise, sensitive

and cost effective for estimating Baclofen using a UV-visible

spectrophotometer.

Materials and Methods

Instrumentation

UV-1800 Shimadzu with UV probe software system were utilized

for qualitative determination of baclofen, digital pH meter,

laboratory centrifuge, brookfield viscometer, stage microscope,

magnetic stirrer, pycnometer.

Reagents and chemicals

Baclofen was purchased from Yarrow Pharma Mumbai, Tween 80

was purchased from Sd Fine chemicals Ltd, Ahmadabad, Span 80

and PEG 400 was purchased from Loba chemicals Ltd Mumbai,

castor oil was purchased from gliter pharmaceutical Rangwasa, Rao,

Each of the ingredients and chemicals are an analytical grade. They

were procured from the GRY institute of pharmacy’s laboratory in

Borawan, India.

Pre formulation studies

Drug excipients compatibility study: FTIR is an effective method

for examining the interaction between drugs and excipients.

Surfactant, co-surfactant and oil were added to the pure medication

individually then KBr pellets are prepared and the resulting mixture

was scanned in the 400 cm-1–4000 cm-1 range. To reduce the

possibility of significant functional groups in the drug interacting

with the excipients, the comparison was conducted using the FTIR

spectrum of the pure drug [9].

Drug solubility analysis: A solubility analysis was carried out in

order to create a new analytical method. Baclofen powder was added

in excess to the solvents water, ethanol, methanol, 0.1 N HCl and

0.1 N NaOH and the mixture was then vortexes. The samples were

left at room temperature for 30 minutes to achieve equilibrium. The

un-dissolved drug was subsequently removed from the equilibrated

samples using sonication for 30 minutes. Then filter the solution

by Whatman filter paper. Before formulating micro emulsion

choose appropriate oil, surfactant, and co surfactant in which drug

shows maximum solubility. The same approach was conducted to

check the solubility of Baclofen in different oil, surfactants and co

surfactants.

Description of analytical method

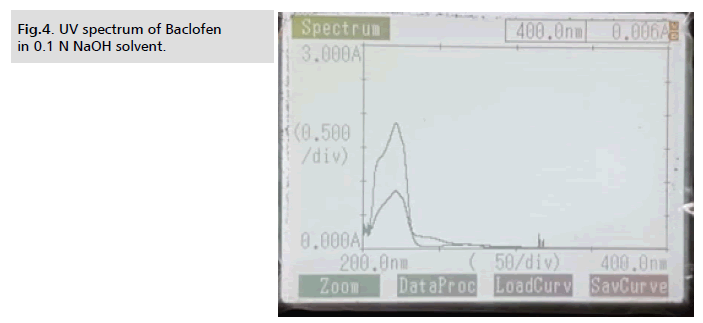

Selection of wavelength: 100 mg pure Baclofen was dissolved in

100 ml of 0.1 N NaOH solution to create a primary stock solution

with a concentration of 1000 μg/ml. This solution was further used

to determine the wavelength of maximum absorption (ƛmax) of

baclofen. Then, 10 ml of primary stock solution was diluted with

100 ml of 0.1 N NaOH solution to make a concentration 100 μg/

ml secondary stock solution. Different concentrations of the drug

dilution (2 μg/ml, 4 μg/ml, 6 μg/ml, 8 μg/ml and 10 μg/ml) were

prepared with the same solvent and then scanned with a UV-visible

spectrophotometer between the wavelengths of 200 nm-400 nm

with a 0.1 N NaOH solution serving as a blank.

Validation of analytical method

Analytical method for Baclofen is validate as per ICH guideline.

The main validation parameters such as linearity and range,

accuracy and precision, recovery, ruggedness, LOD and LOQ were

evaluated in developed method [10-13].

Accuracy: From the stock solutions 4, 6 and 8 μg/ml concentration

dilution were made in 0.1 N NaOH and samples were scan at 221

nm to measure the accuracy. From the absorbance value % purity

was determined and calculates SD and RSD value.

Precision: The precision was determined in the terms of

repeatability, intermediate and reproducibility. 4, 6 and 8 μg/ml

concentration solutions was analysed to determine all parameter

and the relative standard deviation was calculated.

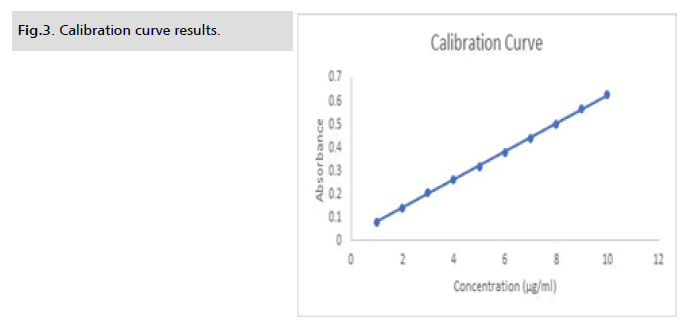

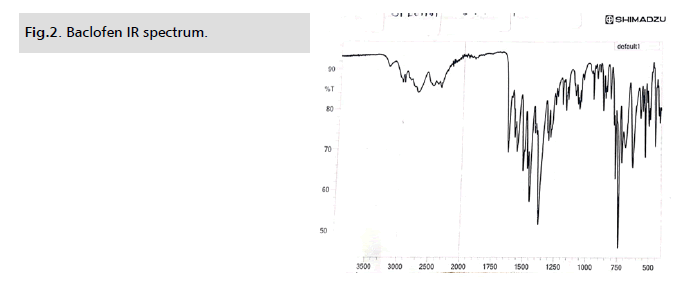

Linearity: A series of dilutions of Baclofen at 1, 2, 3, 4, 5, 6, 7,

8 and 10 g/ml were made and then scanned under a UV light.

A calibration curve was created using the resulting absorbance

data. Further calculations were made by Y-intercept equation's

correlation coefficient.

Determination of LOQ and LOD: LOD and LOQ were

determined to determine the proposed method's sensitivity. The

lowest amount of analyte quantify is LOQ, whereas LOD is the

lowest amount of analyte detectable by the technique. The ICH

recommendations were used to compute the baclofen LOD and

LOQ using the formulas LOD=3.3 /S=0.825 g/ml and LOQ=10

/S=2.5 g /ml.

Range: By comparing the results interval of lower and upper levels

of LOD, it has been possible to define the range of analytical

methods with a reasonable degree of precision and accuracy.

Robustness: The ability of an analytical method to stay unaffected

by slight but intentional changes in the method parameters is

measured as robustness, which gives a clue as to how reliable the

method will be in typical conditions. The robustness of this method

was determined by analyzing of 3 μg/ml and 6 μg/ml concentration

solutions within the day and calculating SD and RSD.

Ruggedness: The robustness of this procedure was assessed by two

analysts analyzing solutions with concentrations of 5 μg/ml and

10 μg/ml on the same equipment. After that, SD and RSD were

calculated.

Formulation of micro emulsion

Castor oil and sesame oil were chosen as the oil phases for the

creation of the o/w micro emulsion based on the solubility

investigation of the drug Baclofen. Tween 80 and span 80 mixture

together used as surfactants and co surfactants; propylene glycol is

used as the polymer and distilled water as the aqueous phase. Four

surfactant-co surfactant ratios (S/Cos ratios) batches, including

3:1, 3.5:1, 4.5:1 and 1.5:1, were tested in the current study. To

make a micro emulsion, Baclofen were dissolved in oil phase and

Surfactant, co surfactant and PEG was blended together to form

a homogeneous mixture (Smix). Oil phase and Smix phase were

mixed slowly with continuous trituration. Water was added drop in

drop to the present mixture which was mixed on a magnetic stirrer

at 3000 rpm at for 30 minutes. The slow and continuous stirring

allows equilibration between oily and aqueous phases. The resulted

mixtures ranged from a milky white, highly turbid, translucent,

and transparent liquid phase. The formation of transparent, freeflowing

mixtures indicated the endpoint of the titration. The

percentage of four different phases oil, water and mixture of

surfactant and co surfactant were calculated [7].

Evaluation parameters of baclofen microemulsion

Optical transparency: After each addition of water, the mixture

of oil, surfactant, or surfactant and co-surfactant was visually

inspected. By visual inspection formulation's colour, phase

separation, creaming and clarity were examined [14].

Viscosity measurement: Using a brook field viscometer, the

optimized formulation's viscosity was assessed without dilution

(DV-E Brookfield Viscometer Model-LVDVE). 500 ml sample

formulation was keeping in beaker, at 350°C ± 2 room temperature

and spindle no. 6, 7 at 60 rpm was used to measure the viscosity at.

For reproducible results, these processes were repeated three times.

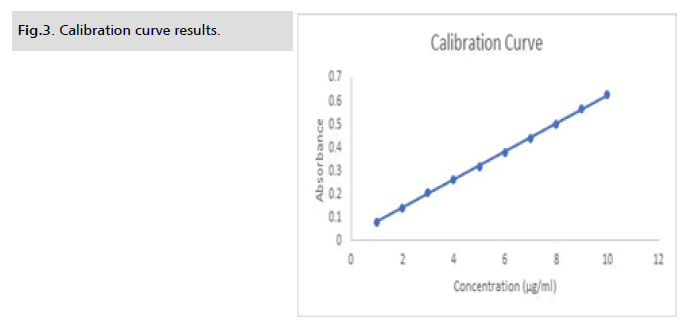

Particle size determination: The stage microscopic method is

used to determine particle size. In this technique, a created micro

emulsion droplet was placed on a piece of glass using a stage

microscope. A 100X eyepiece lens was used to observe the droplet's

size and then particle size calculated [15].

Specific gravity: The density of the micro emulsion and the water

was obtained by using a density bottle and the specific gravity of

the micro emulsion was then calculated using the formula [16].

pH determination: The pH of the micro emulsion obtained was

measured using a digital pH meter at 25°C and calibrated with

phosphate buffer. For greater accuracy, every reading was obtained

in triplicate and the estimate of the triplicates was obtained [17].

Drug content analysis: 5 ml drug micro emulsion was dissolved in

100 ml of 0.1 N NaOH, shake the solution till the micro emulsion

is completely mixed, then kept in centrifugation tube at 3000

rpm for 30 mins. The excess was divided and filtered. From this

solution 0.1 ml solution was diluted to 10 ml with same solvent

then again filtered it. The absorbance was measured at 221 nm

by UV Spectrophotometer using the placebo micro emulsion as a

blank solution and the drug content was calculated.

Stability testing: According to ICH guidelines, the accelerated

ambient stability investigation was carried out in stability chambers

(Thermo laboratories) at temperature at 40 ± 2°C, 25°C and 10°C,

respectively and humidity (75 ± 5% RH). The formulation was kept

in a hermetically screw capped bottle with a volume of around 100

ml. In order to evaluate the physical appearance, phase separation

at accelerated gravity and drug content during the course of the

study's 6 month duration, sample analysis were taken in three

month intervals [18].

Results and Discussion

Interpretation of IR spectra of baclofen and other

excipients

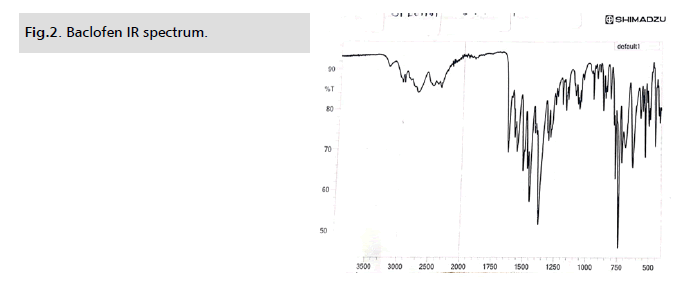

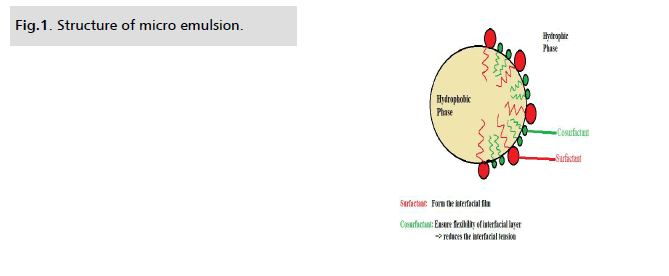

Characteristic absorption bands in the IR spectra of baclofen

can be identified. They are connected to stretching vibrations

of the N-H group of primary amines (3447.89 cm-1), stretching

vibrations of the C-Cl group (664.48 cm-1) and different COOH

group (1729.65 cm-1) vibrations. The IR spectra of combinations

of baclofen with tween 80, span 80, PEG 400, castor oil and honey

contain those particular bands. There has been no change in the

chemical structure of baclofen or its compatibility with other

substances, as evidenced by the presence of all typical bands of the

drug and excipients in the IR spectra of combinations with varied

concentrations of both components (Fig. 1. and Tab. 1.).

Figure 1: Structure of micro emulsion.

| Wave number (cm-1) |

Corresponding functional group and type of molecular vibration |

| 1527.15 |

Aromatic C=C (S) |

| 2817.44 |

Alkane (S) |

| 3447.89 |

Amine N-H (S) |

| 664.48 |

Halogen C-Cl (S) |

| 1729.65 |

Carboxylic acid C=O (S) |

Tab. 1. Peaks observed in infrared spectrum of baclofen.

Solubility

Baclofen shows better solubility with 0.1 N NaOH so it is used as

solvent for analytical method development (Tab. 2.).

| Solvent |

Solubility |

| Water |

Slightly soluble |

| Ethanol |

Partial soluble |

| Methanol |

Partial soluble |

| 0.1 N NaOH |

Soluble |

| 0.1 N HCl |

Soluble |

Tab. 2. Solubility study.

Analytical method results

Different dilutions ranging from 2 g/ml to 10 g/ml were prepared

for the purpose of determining the analytical wavelength and scanned at wavelengths between 200 and 400 nm in a UV visible

spectrophotometer. Maximum absorbance was detected in the

dilutions at 221 nm. Consequently, 221 nm was chosen as the

analytical wavelength (Fig. 2.)

Figure 2: Baclofen IR spectrum.

Validation of analytical method

Analytical method was validated as per ICH guideline. According

to the results of linearity value concentration range from 1 μg/ml

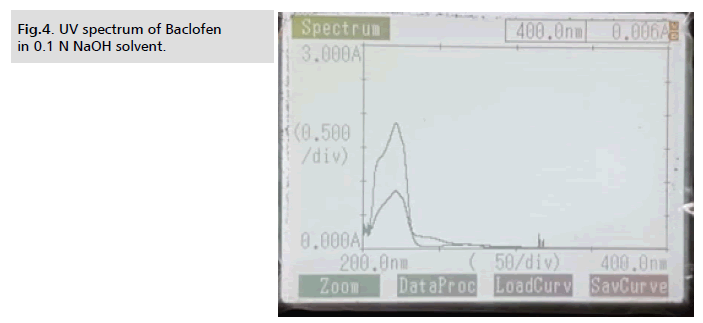

to 10 μg/ml, correlation coefficient equation found to be y=0.0603 X+0.0207 and regression value found to be R2=0.999 (Fig. 3. and Fig. 4.). Accuracy, precision, robustness and ruggedness were

calculated and result value of the relative standard deviation was

not exceeding by 2%. Results of LOD LOQ, range were 0.825 μg/

ml, 2.5 μg/ml, 1 μg/ml, 10 μg/ml respectively (Tab. 3.).

Figure 3: Calibration curve results.

Figure 4: UV spectrum of Baclofen

in 0.1 N NaOH solvent.

| S. no. |

Parameter |

Results |

| 1 |

ƛmax |

221 nm |

| 2 |

Regression equation (y=mx+c) |

Y=0.0603x+0.0207 |

| 3 |

Slope |

0.0603 |

| 4 |

Intercept |

0.0207 |

| 5 |

Correlation coefficient (R2) |

0.9995 |

| 6 |

Accuracy (RSD) |

Less than 2% |

| 7 |

Interday precision (RSD) |

Less than 2% |

| 8 |

Intraday precision (RSD) |

Less than 2% |

| 9 |

Linearity range |

1 µg/ml-10 µg/ml |

| 10 |

LOD |

0.825 µg/ml |

| 11 |

LOQ |

2.5 µg/ml |

| 12 |

Ruggedness1 |

Less than 2% |

| 13 |

Ruggedness2 |

Less than 2% |

| 14 |

Robustness |

Less than 2% |

| 15 |

% Purity of formulation |

99.30% |

Tab. 3. Summary of validation parameters.

Composition formula optimization

Span 80 has a low HLB value with lipophilic properties, which

can be used to form oil-in-water micro emulsions when used in

combination with tween 80 having hydrophilic properties and high

HLB value. The emulsifier’s tween 80 and span 60 are frequently

used in combination. In comparison to using only one surfactant,

the combination of these two surfactants can increase the solubility of drug in water and physical stability of the micro emulsion.

PEG-400 was used as co solvents and polymer for improving the

aqueous solubility of weakly water soluble Baclofen which will

help in improving drug bioavailability. Four different composition

formulas were optimized for fixing the S/Cos ratios (Fig. 5.). Out

of four formulas M1 appear as clear, thermodynamically stable

isotropic liquid mixtures of oil, water and surfactant and their

result of evaluation are mentioned below (Tab. 4.).

Figure 5: Baclofen micro emulsion

formulations.

| Ingredients |

Formulation code (100 ml) |

Purpose |

| F1 |

F2 |

F3 |

F4 |

| Baclofen |

100 mg |

100 mg |

100 mg |

100 mg |

Drug |

| Tween 80 |

30 ml |

33 ml |

28 ml |

32 ml |

Surfactant |

| Span 80 |

10 ml |

6 ml |

13 ml |

10 ml |

Co-surfactant |

| PEG 400 |

8 ml |

8 ml |

8 ml |

10 ml |

Polymer |

| Sesame oil |

- |

32 ml |

16 ml |

14 ml |

Oil phase |

| Castor oil |

32 ml |

- |

16 ml |

16 ml |

Oil phase |

| Rose water |

4 ml |

5 ml |

3 ml |

4 ml |

Fragrance |

| Water |

16 ml |

16 ml |

16 ml |

16 ml |

Aqueous phase |

Tab. 4. Composition formula of baclofen micro emlusion.

Evaluation of formulation

Optical transparency: Micro emulsions are regularly inspected

to check the formulation's color change, phase separation in oil

and water phase, upward and down ward creaming. Through the

examination of physical parameter it was concluded that there

is no colour change and creaming of formulation’s found. Both

the phase’s oil and water were immiscible with each other. Micro

emulsion of Baclofen M1 was transparent and cleared solution.

Viscosity measurement: Using a Brookfield Viscometer, all

the formulation's viscosity was assessed at 35°C ± 2°C room

temperature and 60 rpm. Viscosity of formulation M1 and M4

were found to be 82 and 110 dynes/cm2.

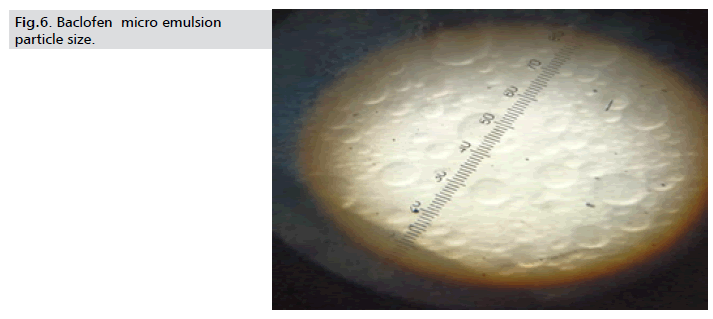

Particle size determination: The rate of phase separation is directly

propositional to the radius of the globules. The particle size of the

formulation found to be in between 100 nm-125 nm, acceptable

range (Fig. 6.).

Figure 6: Baclofen micro emulsion

particle size.

Specific gravity: The density of the micro emulsion was calculated

as compared to water. The specific gravity of the micro emulsion

was found to be 0.89-1.00, equivalent to water.

pH determination: The pH of the micro emulsion was measured

using a digital pH meter. The pH of the formulation M1 found to

be 6.7, which in slightly acids in nature.

Drug content analysis

For each batch of formulation, drug content studies were completed

in triplicate. The calculated drug content was found to be in range

of 89.19% to 96.73%. According to the data, formulation M3

has the least drug, whereas formulation M1 contains the highest

amount shown in (Tab. 5.).

| Parameters |

Formulations |

| M1 |

M2 |

M3 |

M4 |

| Phase separation |

No |

No |

Yes |

Yes |

| Clarity |

Transparent |

Milky |

Milky |

Milky |

| Colour |

Yellowish |

Brown |

White |

Whitish brown |

| Viscosity (dynes/cm2) |

82 |

87 |

95 |

110 |

| Particle size(nm) |

100 |

110 |

118 |

125 |

| Specific gravity |

1 |

0.89 |

0.8 |

0.6 |

| pH |

6.7 |

6.2 |

6.4 |

6.5 |

| Drug content |

96.73%. |

90.32% |

89.19% |

92.45% |

Tab. 5. Result of evaluation parameters of baclofen micro emulsion.

Stability testing

The stability study was carried out to refine the ideal micro emulsion

formulation for harsh environments. After 3 month periods sample

was collected and evaluated. Drug content, pH and viscosity of

best formulation M1 was 95.98%, 6.6 and 81.4 respectively. There

is no phase separation, cracking and coalescence was examined in

the samples.

Conclusion

A micro emulsion of baclofen was successfully formulated. Micro

emulsions have improved the bioavailability, effectiveness, and rate

of absorption of Baclofen in accordance with the objectives of the

current investigation. The optimized formula consists of Tween 80, span 80 and PEG 400 in (3:1) ration. A FTIR investigation found

that the excipients and the medication were compatible. Utilising

0.1 N NaOH solution the analytical method was validated and It

was accurate, precise and economical. M1 batch had all the desired

characteristics and a drug content of 96.73% across all batches.

On the bases of results, it was concluded that the micro emulsion

formulation of Baclofen is a potential and effective formulation for

oral delivery that will increase bioavailability.

Acknowledgements

Without the assistance of Dr. Sujit Pillai, Mr. Sumit Patel, Ms.

Aakansha Mahajan and my family, this research would not have

been feasible. I'd like to take this initiative to thank GRY Institute

of Pharmacy for providing the required equipment and materials to

enable me to conduct the research project.

Author's Contribution

(A) Study Design · (B) Data Collection . (C) Statistical

Analysis · (D) Data Interpretation · (E) Manuscript Preparation · (F) Literature Search

· (G) No Fund Collection

References

- Chauhan L, Thakur P, Sharma S. Microemulsions: New vista in novel drug delivery system. Innov Pharm Pharmacother. 2019; 7:37-44.

[Google Scholar]

- Gibaud S, Attivi D. Micro emulsions for oral administration and their therapeutic applications. Expert Opin Drug Deliv. 2012; 9: 937-951.

[Crossref] [Google Scholar] [PubMed]

- Madhav S, Gupta D. A review on micro emulsion based system. Int J Pharm Sci Res. 2011; 2(8): 1888-1899.

[Google Scholar]

- Saini JK, Nautiyal U, Kumar M, et al. Micro emulsions: A potential novel drug delivery system. Int J Pharm Sci Res. 2014;2: 15-20.

[Google Scholar]

- Jadhav A, Daundkar A, Morale D, et al. Review on: Micro emulsion a novel approach for drug delivery. Int J Pharm Sci Rev Res. 2018;11: 60-65.

[Google Scholar]

- Katiyar BS, Katiyar SS, Mishra PS, et al. Micro emulsions: A novel drug carrier system. Int J Pharm Sci Rev Res. 2013;20: 138-148.

[Google Scholar]

- Adhao VS, Thenge RR. Development and validation of stability indicating high performance liquid chromatography method for determination of baclofen. Res Artic American J Pharm Tech Res. 2017;7:544-556.

[Google Scholar]

- Rojek B, Wesolowski M, Suchacz B. Detection of compatibility between baclofen and excipients with aid of infrared spectroscopy and chemo metry. Spectrochim Acta A Mol Biomol Spectrosc. 2013;116: 532-538.

[Crossref] [Google Scholar] [PubMed]

- Potdar M. Pharmaceutical quality assurance. Nirali prakashan. 2017;6: 8.29-8.31.

- ICH Harmonised Tripartite Guideline. Validation of analytical procedures: Text and methodology, Geneva: IFPMA. 1996;1-5.

- Gabhane KB, Jaiswal A, Tapae KK. Simple and validated ultraviolet spectrophotometric method for the estimation of baclofen in bulk form. Res J Pharm Biol Chem Sci. 2014;5: 104-109.

[Google Scholar]

- Lotfi B, Ghorbel A, HassineT. Baclofen pharma profile. Article in compendium yardley, PA. 2007: 629-632.

- Katiyar B, Katiyar S. Micro emulsions: A novel drug carrier system. Int J Pharm Sci. 2013;20: 138.

- Gui Sh Y, Wu L, Peng DY, et al. Preparation and evaluation of a micro emulsion for oral delivery of berberine. Pharmazie. 2088;63: 516–519.

[Crossref] [Google Scholar] [PubMed]

- Yadav V, Jadhav P, Kanase K, et al. Preparation and evaluation of microemulsion containing antihypertensive drug. Int J Appl Pharm. 2018;10: 138-146. [Crossref] [Google Scholar] [PubMed]

- Panghal A, Sachdeva M, Agarwal V. Formulation and development of baclofen micro emulsion incorporated into transdermal patch. J Drug deliv Ther. 2022; 12: 55-63.

[Google Scholar]

- Nath R, Bhowmik R, Chakraborty R, et al. Preparation and evaluation of a novel oral micro emulsion drug delivery system for enhancing the bioavailability of Diltiazem. Int J Pharm Sci Rev Res. 2021;70: 164-70.

[Google Scholar]

- Badawi A, Nour S, Sakran W, et al. Preparation and evaluation of micro emulsion systems containing salicylic acid. AAPS Pharm Sci Tech. 2009;10: 1081-1084.

[Crossref] [Google Scholar] [PubMed]