Ruth EG* and Chika MJ

Faculty of Pharmaceutical Sciences, Department of Pharmaceutical and Medicinal Chemistry, University of Nigeria, Nsukka, Nigeria

*Corresponding Author:

Ruth EG

Faculty of Pharmaceutical Sciences

Department of Pharmaceutical and Medicinal Chemistry

University of Nigeria, Nsukka, Nigeria.

Tel: +2348066167789

E-mail:ruth.elefe.pg76968@unn.edu.ng

Received date: September 18, 2018; Accepted date: October 22, 2018; Published date: October 29, 2018

Citation: Ruth EG, Chika MJ (2018) Influence of Cosolvents and Surfactants on the Rate Constant (Log K) of Sparfloxacin. Transl Biomed Vol.9 No.4:155. doi:10.21767/2172-0479.100155

Keywords

Sparfloxacin; Degradation kinetics; Cosolvents; Surfactants; Rate constant

Introduction

Sparfloxacin (Figure 1), chemically defined as 5-amino-1- cyclopropyl-7-(cis-3, 5-dimethyl-1- piperazinyl)-6, 8-difluoro-1, 4-dihydro-4-oxo-3-quinolinecarboxylic acid is a difluoroquinolone antibacterial agent belonging to the third generation quinolones. It is insoluble in water [1]. In clinical practice, sparfloxacin is used to treat streptococci and community-acquired lower respiratory tract infections [2-5] Figure 1. Its mechanism of action involves inhibition of DNA synthesis by promoting cleavage of bacterial DNA in the DNA-enzyme complexes of DNA gyrase and type IV topoisomerase, therefore resulting in rapid bacterial death [6]. Spar?oxacin is water-insoluble and belongs to class II of the Bio pharmaceutics classification System. Cosolvents are organic compounds found to be substantially miscible with water [7]. They have been reported to have significant effects on the rate constants of chemical compounds. [8,9]. Surfactants are amphiphilic molecules composing of a hydrophilic polar moiety (head) and a hydrophobic non-polar moiety (tail) and capable of forming colloidal-sized clusters in solutions, called micelles [10]. Surfactants have also been reported to have great influence on the rate constants of chemical compounds [11]. Previous study [12] has shown that sparfloxacin undergoes degradation under acidic conditions. Literature search has revealed that no study has been done to investigate the influence of cosolvents and surfactants on sparfloxacin degradation. Therefore, this study was aimed at determining the influence of cosolvents and surfactants on the rate constant of sparfloxacin by investigating its degradation kinetics in acidic aqueous solution.

Figure 1: Chemical structure of sparfloxacin.

Materials and Methods

Materials

Sparfloxacin (Baroque Pharmaceuticals PVT. Ltd, India), glycerol, propylene glycol, polyethylene glycol 400, sodium lauryl sulphate and polysorbate 80 (tween 80). All were purchased from Sigma- Aldrich, USA. Methanol, hydrochloric acid and sodium hydroxide (Fisher Scientific, USA. UV/Vis Spectrophotometer (Shimadzu, Japan).

Sample preparation

Standard stock solution of 200 μg/ml of sparfloxacin was prepared by dissolving accurately weighed 10 mg of sparfloxacin in 50 ml of methanol. The stock solution was used to obtain the wavelength of maximum absorption of the drug by scanning with a UV/V is Spectrophotometer. Dilution of the stock solution was done to obtain concentrations of 1, 2, 3, 4 and 5 μg/ml respectively. The absorbance readings of these concentrations were taken at wavelength of 304 nm to obtain the calibration graph of sparfloxacin.

Vehicle preparation

A 0.1 M HCl solution was prepared by diluting 8.3 ml of concentrated HCl in distilled water and diluted to 1000 ml with distilled water, while 0.1 M NaOH was prepared by dissolving 4 gms of NaOH pellets in distilled water and making the final volume up to 100 ml with distilled water. A stock solution of 25% w/v of the three cosolvents used were prepared by weighing 25 gms of each cosolvent into a beaker, dissolving in distilled water, and the volume made up to 100 ml in a volumetric flask with distilled water. Dilution of the stock solution was made in 0.1 M HCl solution to obtain concentrations of 20% w/v, 15% w/v, 10% w/v, 5% w/v respectively. Similarly, a stock solution of 2.0% w/v of the two surfactants used were prepared by weighing 2 gms of each surfactant into a beaker and dissolving in distilled water, and the volume made up to 100 ml in a volumetric flask with distilled water. Dilution of the stock solution was made in 0.1 M HCl solution to obtain concentrations of 1.0% w/v, 0.5% w/v, 0.2% w/v, 0.1% w/v respectively.

Kinetic study

The kinetic study was done by introducing 1 ml of the drug stock solution (200 μg/ml) into a 10 ml volumetric flask, diluted to volume with various percentage solutions of the cosolvent and surfactant respectively. The solutions were transferred into vials, capped and placed into a water bath at a temperature of 600°C. At intervals of 30 mins, samples were withdrawn from the water bath and analysed spectrophotometrically at a maximum wavelength of 304 nm. A plot of log percent remaining of the drug versus time was carried out to obtain the rate constant.

Results

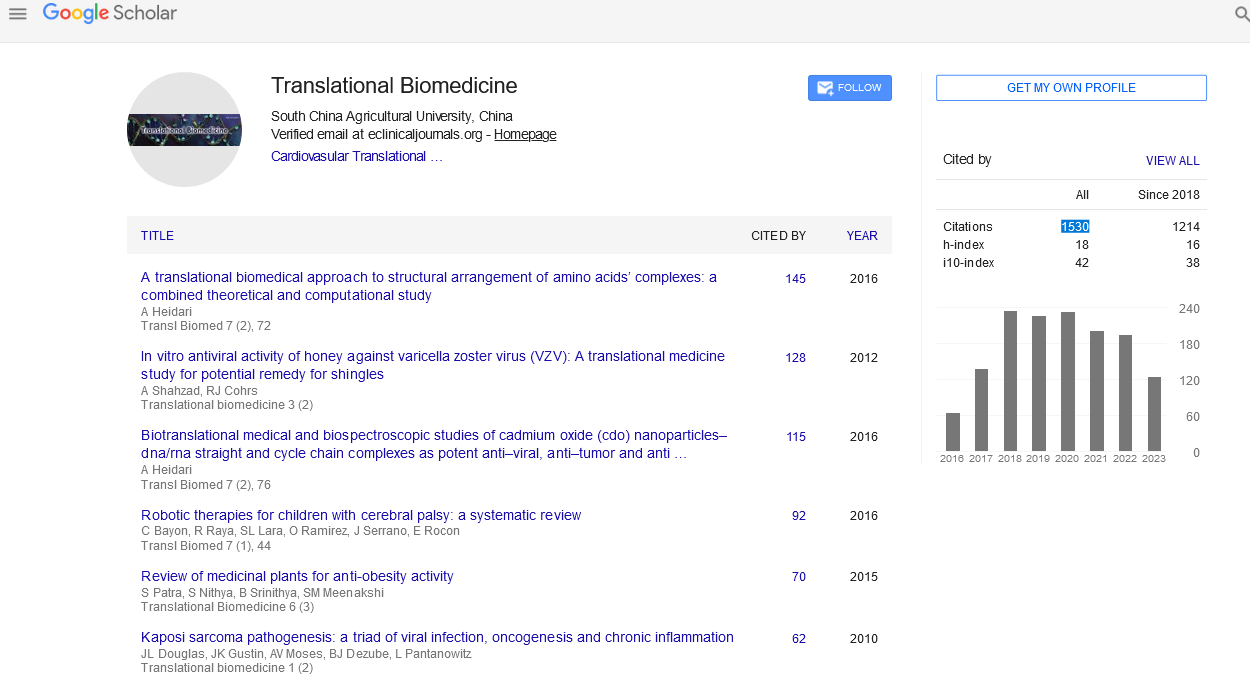

The calibration graph of sparfloxacin obtained by plotting absorbance versus concentration gave a linear curve. Beer’s law was obeyed in the concentration range of 1-5 μg/ml. The regression equation for the linear graph is A=0.0505C+0.002. The results of the kinetic studies of sparfloxacin in cosolvent acidic solutions are presented in Figures 2-4 while that of surfactant solutions are given in Figures 5 and 6. The results showed that the plot of logarithm of percent sparfloxacin remaining versus time gave linear curves for all the vehicles investigated. The effects of the cosolvents and surfactants on the rate constant are presented in Tables 1 and 2 respectively. The results showed that all the vehicles studied decreased the rate constant.

Figure 2: Effect of glycerol on the degradation kinetics of sparfloxacin.

Figure 3: Effect of propylene glycol on the degradation kinetics of sparfloxacin.

Figure 3: Effect of polyethylene glycol400 on the degradation kinetics of sparfloxacin.

Figure 5: Effect of tween 80 on the degradation kinetics of sparfloxacin.

Figure 6: Effect of sodium lauryl sulphate on the degradation kinetics of sparfloxacin.

| Rate constant (k) |

| % Cosolvent |

Glycerol |

Propylene glycol |

Polyethylene glycol |

| 5 |

0.00702 |

0.00652 |

0.01043 |

| 10 |

0.00603 |

0.00095 |

0.00493 |

| 15 |

0.00603 |

0.0008 |

0.0035 |

| 20 |

0.00176 |

0.00074 |

0.00052 |

| 25 |

0.00033 |

0.00045 |

0.00047 |

Table 1: Effect of cosolvents on the rate constant of sparfloxacin.

| Rate constant (k) |

| % w/v Surfactant |

Polysorbate 80 |

Sodium lauryl sulphate |

| 0.1 |

0.00251 |

0.00373 |

| 0.2 |

0.00114 |

0.00091 |

| 0.5 |

0.00044 |

0.00077 |

| 1 |

0.00038 |

0.00036 |

| 2 |

0.00032 |

0.00027 |

Table 2: Effect of surfactant on the rate constant of sparfloxacin.

Discussion

Chemical stability of pharmaceutical active agents is a matter of great concern as it affects efficacy and safety of the drug product. Cosolvents and surfactants are among the techniques used to stabilize drug degradations. The linearity of the calibration curve was confirmed by regression correlation coefficient (R2) value of 0.9881. In the kinetic study, a plot of logarithm of percent drug remaining versus time gave a linear graph for each vehicle studied. The slopes of the linear graphs allowed the rate constants to be evaluated. The rate constant obtained in 0.1 M HCl solution was used as a control in evaluating the effect of the studied vehicles on the rate constant of sparfloxacin. Previous studies have used plots of logarithm of percent drug remaining versus time to calculate kinetic rate constants of drugs [9,13]. A general hypothetical rate equation for sparfloxacin degradation as a function of 0.1 M HCl can be written as, kobs=ko+k[H+], where kobs is the overall observed rate constant, ko is the water catalysis rate constant, k[H+] is the hydrogen ion catalysis rate constant. The water catalysis rate constant is an apparent firstorder rate constant while the hydrogen ion catalysis rate constant is second-order rate constant. The degradation of sparfloxacin in these vehicles (cosolvent and surfactant solutions) followed first-order rate kinetics. The rate constant decreased as the content of each vehicle was increased. It was also observed that glycerol showed most decreasing effect on the rate constant of sparfloxacin than the other cosolvent systems at the maximum concentration (20.0% w/v) studied. The stabilization effect of the cosolvent on sparfloxacin degradation may perhaps be due to decrease in dielectric constant and changes in viscosity of the solutions. A plot of logarithm of the rate constant versus cosolvent concentration showed a linear relationship. Similarly, it was noted that sodium lauryl sulphate showed slightly more decreasing effect on the rate constant of sparfloxacin than polysorbate 80 (tween 80) at the maximum concentration (2.0% w/v) investigated. A linear relationship was also observed when logarithm of the rate constant versus cosolvent concentration was plotted. The effect of surfactants on the rate constants might be due to micelle formation or a combination of micelle formation and pH effects. In this investigation, no attempt was made to carry out effects of buffers, ionic strength, pH, temperature on the sparfloxacin degradation or characterize the degradation products because information on them has been reported [12]. However, a plausible reaction mechanism of the hydrolysis is the decarboxylation of the drug molecule.

Conclusion

The breakdown of sparfloxacin was found to be first-order rate kinetics and the hydrolytic reaction was hydrogen ion catalysed. Glycerol exhibited greatest stabilizing properties on the rate constant of sparfloxacin than propylene glycol and polyethylene glycol 400 respectively. Similarly, sodium lauryl sulphate showed greater stabilizing effect on the rate constant of sparfloxacin than polysorbate 80. Finally, the study suggests that the incorporation of cosolvents or surfactants investigated into liquid pharmaceutical dosage forms containing sparfloxacin would enhance the stability of the drug under acidic conditions.

Conflict of Interest

Authors declared that they had no conflict of interest.

23670

References

- Mbah CJ, Ozuo CO (2011) Effect of surfactants on the solubility and intrinsic dissolution rate of sparfloxacin. Pharmazie 66: 192-194.

- Rubinstein E (1996) Safety profile of sparfloxacin in the treatment of respiratory tract infections. J Antimicrob Chemother 37: 145-160.

- Goa KL, Bryson HM, Markham A (1997) Sparfloxacin: A review of its antibacterial activity, pharmacokinetic properties, clinical efficacy and tolerability in lower respiratory tract infections. Drugs 53: 700-725.

- Stein GE, Havlichek DH (1997) Sparfloxacin: Potential clinical and economic impact in the treatment of respiratory infections. Pharmacotherapy 17: 139-147.

- Zhanel GG, Ennis K, Vercaigne L, Walkty A, Gin AS, et al. (2002) A critical review of the fluoroquinolones: Focus on respiratory infections. Drugs 62: 13-59.

- Zhao L, Li P, Yalkowsky SH (1999) Solubilization of fluasterone. J Pharm Sci 88: 967-969.

- Mbah CJ (2010) Degradation kinetics of benzyl nicotinate in aqueous solution. Indian J Pharm Sci 72: 40-43.

- Tu Y, Wang D, Allen LV (1990) Nefopam hydrochloride degradation kinetics in solution. J Pharm Sci 79: 48-52.

- Alkhamis KA, Allaboun H, Al-Momani WY (2003) Study of the solubilization of gliclazide by aqueous micellar solutions. J Pharm Sci 92: 839-846.

- Hoppe K, Sznitowska M (2014) The effect of polysorbate 20 on solubility and stability of candesartan cilexetil in dissolution media. AAPS Pharm Sci Tech 15: 1116-1125.

- Morimura T, Nobuhara Y, Matsukura H (1996) Thermo-degradation kinetics of the new antibacterial fluoroquinolone derivative, sparfloxacin, in aqueous solution. Chemical and Pharmaceutical Bulletin 44: 1618–1620.

- Ha I, Woo HO, Lee JT, Kang TS, Tak KK, et al. (1996) Degradation kinetics of growth hormone-releasing hexapeptide (GHRP-6) in aqueous solution. Int J Pharm 144: 91-97.