Keywords

Dental implant; CAD/CAM system; Dental prosthesis; Clinical research

Introduction

Since 1980s, the use of CAD/CAM (Computer Aided Design/ Computer Aided Manufacturing) systems in dentistry came into force. The CAD/CAM system was introduced in dentistry with the purpose of promoting the manufacture of prostheses based on the last generation three-dimensional system [1]. Where the search for aesthetic solutions has been increasingly challenging, given the patient's demand and the growing number of techniques and materials available for protective rehabilitation [2]. It aims at the resistance of the material being the primary factor to determine the indication of the technique as well as the preservation of rehabilitation over time and the need for movements that lead to the possibility of performing rehabilitations of larger extensions [1,2].

The CAD/CAM system consists of the intraoral scanner or the plaster model such as CAD, while the CAM is the milling machine, that is, the design of a prosthetic structure in a computer followed by its milling machine [3,4]. Several ceramic systems are available in the market; making professionals in the area require constant recycling according to their properties and indications [5]. Most used are, ceramic are the main alternative restorative material for dental structure due to its favorable properties, such as: compressive strength, thermal conductivity, similarity to dental tissues, radiopacity, marginal integrity and color stability [5,6].

As a literary support, one study evaluated 22 patients and 79 implants. The mean follow-up was 38.4 ± 13.2 months. There were no cases of intraoperative sinus membrane perforation or other complications, and patients reported a high degree of satisfaction. At the end of the follow-up, all prostheses and implants were successful. The elevation of the sinus of the low window appears to be an effective technique to reduce the risk of sinus membrane perforation and postoperative discomfort of the patient in the enlargement of the lateral sinus [1].

One of the main objectives of this technology is the simplification and optimization in the production of prosthetic structures, aiming at the production of structures with high quality and aesthetics, in a personalized and planned way with digital precision [3-6]. With the advancement of technology and dental innovations, perfecting digital printing systems, we need to know if these systems achieve the same levels of precision as conventional printing techniques. It is undeniable that modern dentistry has sought treatment methods that increasingly combine esthetics, durability, ease of execution and time savings, both for the professional and for the patient [6,7].

The technological progress that occurs in diverse fields of science applies to the dental area and has collaborated in the development [8]. And it is of fundamental importance to seek the correct indication of the materials through clinical needs, knowing their advantages and disadvantages presented by each of the systems [9].

The present work aimed to present the main benefits of the CAD/CAM system for the creation of dental prostheses, making historical research and its relevance in contemporary dentistry.

Methods

Experimental and clinical studies were included (case reports, retrospective, prospective and randomized trials) with qualitative and/or quantitative analysis. Initially, the key words were determined by searching the DeCS tool (Descriptors in PubMed, Health Sciences, BIREME base) and later verified and validated by MeSh system (Medical Subject Headings, the US National Library of Medicine) in order to achieve consistent search.

Mesh terms

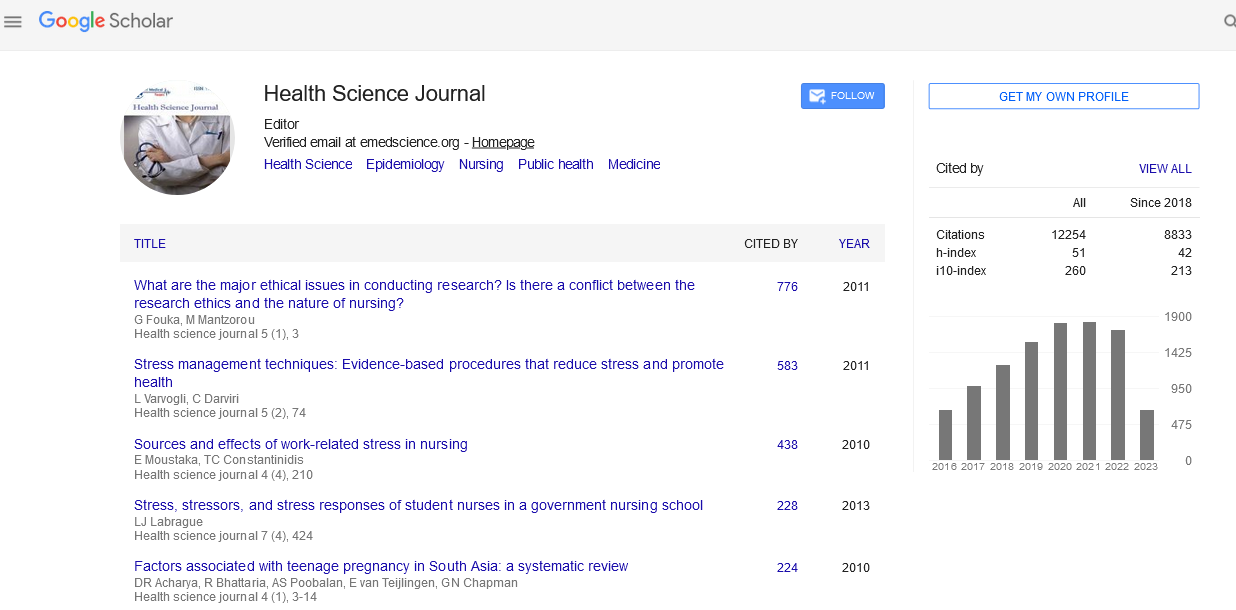

The words were included Dental Implant, CAD/CAM system and Dental Prostheses and Dental implants. The literature search was conducted through online databases: Pubmed, Cochrane Library, Ovid, Scopus and Harvard Library, and Google Scholar. It was stipulated deadline, and the related search covering all available literature on virtual libraries.

Series of articles and eligibility

A total of 55 articles were found involving CAD/CAM system. Initially, it was held the exclusion existing title and duplications in accordance with the interest described this work. After this process, the summaries were evaluated and a new exclusion was held. A total of 36 articles were evaluated in full and 31 were included and discussed in this study.

Results and Discussion

Based on the main literary findings, the best results of a study were found for the crowns manufactured using the CAD/CAM system. Statistical analysis revealed no significant difference between the groups for vertical misalignment (p=0.721) [2]. There was no significant difference (p>0.05) for the internal and horizontal marginal misalignment in three groups, but it was found only in one CAD group (p≤0.05). The qualitative analysis revealed that most of the samples of the fused groups exhibited a subextension of the crowns, whereas a CAD group presented superextension. The crown manufacturing method influenced the accuracy of the marginal fit between the prosthesis and the implant [2].

In this context, when the tested materials were used with the CAD/CAM system, the marginal 3D discrepancy of the CAD/CAM frameworks was lower than that of the titanium or zirconia structures [4]. The CAD/CAM system has been widely accepted and can be used in dental laboratories or dental offices [10-15].

Many studies have had the curiosity to analyze the adaptation of prostheses and infrastructures made by means of CAD/CAM systems and to compare them with conventional methods, some have found better results for CAD/CAM systems [16-25] and others for conventional methods [15,21,26-30]. However, it is known that misadaptations can compromise the longevity and success of dental restorations [20-22,31]. Passive adaptation and good marginal adaptation are essential factors in decreasing mechanical and biological complications [18,22,31].

In addition, there is no consensus in the literature of clinically acceptable maladaptive values for implanted prostheses. Although one cannot yet quantify what is actually acceptable, it is known that the gold standard is below 16 pm [24]. The vertical and horizontal maladjustments at the prosthetic interface in implant-supported infrastructures can be evaluated by some tests, such as clinical probing, direct vision, single screw test and radiographic image evaluations [26]. In this way, using available clinical methods can help achieve better infrastructure adaptations. In laboratory studies, the Scanning Electron Microscope is a very useful tool for the analysis and measurement of these maladaptations [17,18].

Still, Ortorp et al. [21] carried out this study with the objective of evaluating the clinical and radiographic performance of titanium prostheses made with CAD/CAM System compared to conventional gold alloy prostheses. For this study, 126 edentulous patients were rehabilitated. The patients were randomly divided into 67 prostheses with titanium structures (23 in maxilla and 44 in mandibles) and 62 conventional prostheses with gold alloy pieces (31 in maxilla and 31 mandibles). Five year clinical and radiographic data were collected for the test and control groups. For both groups, the complications were low, and the clinical and radiological performances were similar. In the conventional group, the 5- year cumulative survival rates were 94.9% and 98.3% for titanium implants and prostheses, respectively. For the CNC group the same rates were 97.9% and 98.2%.

In addition, Drago et al. [20] carried out this present work with the objective of bringing a view of the current state of the CAD/CAM process for dentists and dental prosthodontists and their application in modern implantology. In this work, it was highlighted the use of the 30 encode system, this specific system does not require the expensive investment of laboratories in sophisticated scanners, and CAM. The system has some limitations; it should not be used when you have less than 1.0 mm of gingiva or when you have a variation of one of the implants in more than 30 degrees of the others. The author concludes that the system reduces dentist's chair time, laboratory labor time, decreases costs and increases the seating precision and biocompatibility of dentures made in this way.

In another study, Borba et al. [16] measured the marginal and internal adaptation of total ceramic dentures, containing three elements, manufactured by the CEREC CAD/CAM system using the micro CT measurement technique. Two materials were used for the construction of infrastructures: Vita ln-ceram YZ and Vita In-Ceram Zirconia. Thus, two hypotheses were tested: there would be no difference between the marginal and internal mismatch between the two systems tested and there would be a difference between the mismatches measured at different locations for both systems. The difference between the blocks is that the first one when being machined requires a sintering process to achieve resistance because they are machined in less resistance and this process also reduces the size by about twenty percent. The results obtained at each measurement site were compared and there was no significant difference. However, the results of the same points of the same piece were used to compare the materials. IZ ceramics showed significantly higher mean values of maladjustment than YZ for MG, CA and OA sites. No statistical differences were found between the average values obtained for AOT and the two ceramic materials.

In another study, Rinke et al. [23] (CAD) and milling (CAM) to obtain an ideal tilting slope (abutment with 4 degrees, axial height between 4-5 mm). The hypothesis of this work was that there would be significant differences in the marginal adaptation of zirconia infrastructure developed using different CAD and CAM systems. Sixty samples (n=60) were fabricated using two different scanner systems and two milling systems (CAM). It was found that the variables of manual adaptation and the CAD and CAM system had multiple significant effects on marginal adaptation results. Thus, the authors of this work suggest that the manual adaptation process should preferably be used to ensure better clamping precision for zirconia restorations in the CAD/CAM system.

In the studies of Anadioti et al. [15], the marginal value of fully ceramic crowns made from two printing techniques (digital versus conventional) and two manufacturing methods (CAM versus conventional) was evaluated in vitro. A tooth was prepared with the characteristics of a preparation for a fully ceramic crown (called the master preparation). From this preparation, 30 molds were made with polyvinylsiloxane (PVS) and thirty resin models made. Another thirty resin models were produced from thirty scans with the Lava Chairside Oral system. These sixty models were divided into four groups (n=15). Of the thirty first models, fifteen crowns were made with the emax press (Group 1) and the other fifteen with the emax CAD (Group 1). The other thirty models, scanned with the E4D scanner, were also made in two other forms, fifteen with the emax press (Group 3), and fifteen with the emax CAD (Group 4). All assessments were made in the master's preparation. The results revealed a significant interaction between printing techniques and crown manufacturing methods. The combination of the PVS printing method and the pressed emax technique produced the most accurate marginal margin values.

In more recent years, Neves et al. [17] performed a work to evaluate the influence of different methods of image acquisition. Thus, the marginal adjustment of crowns manufactured using a CAD/CAM system was evaluated by means of computed microtomography, with different methods of acquisition of virtual models. All crowns were made from a mold of the same preparation, in this case, preparation of a human premolar. Four methods of virtual model acquisition were used: Group 1 (control), fingerprint of a tipodont; Group 2, digital printing of a tipodont with the presence of opacifying powder; Group 3, fingerprint of a regular print and Group 4, fingerprint of a master model. Statistically significant differences were found between the marginal gap of Group 2 and the other groups (p<0.05).

In addition, Kocaagaoglu et al. [14] stated that acceptable marginal, axial and occlusal adaptations are essential factors that can ensure a good longevity of the restorations. Thus, the effects of fingerprint protocols on the marginal, axial and occlusal adaptation of zirconia copings were analyzed in vitro. For this, 30 upper premolar teeth extracted without caries or defects were used. The teeth were prepared for zirconia crowns and randomly divided into 3 groups. The zirconia copings were designed with a thickness of 0.5 mm and 30 mm of internal space starting from 1.0 mm from the preparation margin. They were produced using a CAD/CAM protocol with a conventional printing (Cn group) and two different production protocols with group C fingerprints (CEREC system) and Tr group (scanning with the trios scanner, 3 shape). The mean marginal discrepancy values were 85.6 æm for the Cn group, 58.7 æm for the C group and 47.7 æm for the Tr group. Significant differences were found between the production protocols in the marginal, axial and occlusal discrepancies (p<0.05) and the Tr group revealed the smallest axial discrepancy (p<0.05). Thus, the copings produced with the aid of digital printing systems presented better marginal and occlusal adaptation than the copings produced with the aid of conventional printing.

Conclusion

The use of digital tools for the automated manufacturing of implant and prosthesis parts (CAD/CAM system) is a viable reality in dentistry. This system produces high-quality, standardized, accurate prosthetic restorations with perfect detail.

24523

References

- Zaniol T, Zaniol A, Tedesco A, Ravazzolo S (2018) The low window sinus lift: A CAD-CAM-guided surgical technique for lateral sinus augmentation: A retrospective case series. Implant Dent 27: 512-520.

- Moris ICM, Monteiro SB, Martins R, Ribeiro RF, Gomes EA (2018) Influence of manufacturing methods of implant-supported crowns on external and internal marginal fit: a micro-ct analysis. Biomed Res Int 23: 5049605.

- Pesce P, Pera F, Setti P, Menini M (2018) Precision and accuracy of a digital impression scanner in full-arch implant rehabilitation. Int J Prosthodont 31: 171-175.

- Yilmaz B, Kale E, Johnston WM (2017) Marginal discrepancy of CAD-CAM complete-arch fixed implant-supported frameworks. J Prosthet Dent S0022-3913(30835-1.

- Spies BC, Pieralli S, Vach K, Kohal RJ (2017) CAD/CAM-fabricated ceramic implant-supported single crowns made from lithium disilicate: Final results of a 5-year prospective cohort study. Clin Implant Dent Relat Res 19: 1-8.

- Sheridan RR, Verrett R, Haney S, Schoolfield J (2017) Effect of Split-file digital workflow on crown margin adaptation. J Prosthodont 19: 876-883.

- Christensen GJ (2008) In-ofÃÂÃÂÃÂâÂÂÃÂâÂÂÃÂïÃÂÃÂââ¬Ã

¡ÃÂâÂÂÃÂìÃÂÃÂââ¬Ã

¡ÃÂâÂÂÃÂÃÂce CAD/CAM milling of restorations: the future? J Am Dent Assoc 139: 83-85.

- Trost L, Stines S, Burt L (2006) Making informed decisions about incorporating a CAD/CAM system into dental practice. J Am Dent Assoc 137: 32S-36S.

- Batson ER, Cooper LF, Duqum I, Mendonca . (2014) Clinical outcomes of three different crown systems with CAD/CAM technology. J Prosthet Dent 112: 770-777.

- Tamac E, Toksavul S, Toman M (2014) Clinical marginal and internal adaptation of CAD/CAM milling, laser sintering, and cast metal ceramic crowns. J Prosthet Dent 112: 909-913.

- Euan R (2014) Marginal adaptation of zirconium dioxide copings: Influence of the CAD/CAM system and the finish line design. J Prosthet Dent 16: 1-8.

- Buchi DL, Ebler SH, Hämmerle CH, Sailer I (2014) Marginal and internal fit of curved anterior CAD/CAM-milled zirconia fixed dental prostheses: an in-vitro study. Quintessence Int 45: 837-846.

- Kayatt FE, Neves FD (2013) Application of CAD/CAM systems in restorative dentistry. Publisher Elsevier. (1st Edn.).

- Kocaagaoglu H, Kilinc Hl, Albayrak H (2017) Effect of digital impressions and production protocols on the adaptation of zirconia copings. J Prosthet Dent 117: 102-108.

- Anadioti E, Aquilino SA, Gratton DG, Holloway JA, Denry I, et al. (2014) 3D and 2D marginal fit of pressed and CAD/CAM lithium disilicate crowns made from digital and conventional impressions. J Prosthodont 23: 610-617.

- Borba M, Cesar PF, Griggs JA, Della Bona A (2011) Adaptation of all-ceramic fixed partial dentures. Dent Mater 27: 1119-1126.

- Das Neves FD, Do Prado CJ, Prudente MS, Carneiro TA, Zancope K, et al. (2015) Microcomputed tomography marginal fit evaluation of computeraided design/computer-aided manufacturing crowns with different methods of virtual model acquisition. Gen Dent 63: 39-42.

- De Franca DG, Morais MH, Das Neves FD, Barbosa GA (2015) Influence of CAD/CAM on the fit accuracy of implant-supported zirconia and cobaltchromium fixed dental prostheses. J Prosthet Dent 113: 22-28.

- Drago C, Saldarriaga RL, Domagala D, Almasri R (2010) Volumetric determination of the amount of misfit in CAD/CAM and cast implant frameworks: a multicenter laboratory study. Int J Oral Maxillofac Implants 25: 920-929.

- Drago CJ (2006) Two new clinical/laboratory protocols for CAD/CAM implant restorations. J Am Dent Assoc 137: 794-800.

- Ortorp A, Jemt T (2004) Clinical experiences of computer numeric control-mi I led titanium frameworks supported by implants in the edentulous jaw: a 5-year prospective study. Clin Implant Dent Relat Res 6: 199-209.

- Resende CC, Castro CG, Pereira LM, Prudente MS, Zancope K, et al. (2015) Influence of the Prosthetic Index Into Morse Taper Implants on Bacterial Microleakage. Implant Dent 24: 547-551.

- Rinke S, Fornefett D, Gersdorff N, Lange K, Roediger M (2012) Multifactorial analysis of the impact of different manufacturing processes on the marginal fit of zirconia copings. Dent Mater J 31: 601-609.

- Sartori IA, Ribeiro RF, Francischone CE, de Mattos Mda G (2004) In vitro comparative analysis of the fit of gold alloy or commercially pure titanium implant-supported prostheses before and after electroerosion. J Prosthet Dent 92: 132-138.

- Guth JF, Keul C, Stimmelmayr M, Beuer F, Edelhoff D (2013) Accuracy of digital models obtained by direct and indirect data capturing. Clin Oral Investig 17: 1201-1208.

- Kan JY, Rungcharassaeng K, Bohsali K, Goodacre CJ, Lang BR (1999) Clinical methods for evaluating implant framework fit. J Prosthet Dent 81: 7-13.

- Patzelt SB, Spies BC, Kohal RJ (2015) CAD/CAM-fabricated implantsupported restorations: a systematic review. Clin Oral Implants Res 26: 77-85.

- Van Noort R (2012) The future of dental devices is digital. Dent Mater 28: 3-12.

- Guess PC, Zavanelli RA, Silva NR, Bonfante EA, Coelho PG, et al. (2010) Monolithic CAD/CAM lithium disilicate versus veneered YTzp crowns: comparison of failure modes and reliability after fatigue. Int J Prosthodont 23: 434-442.

- Cooper LF, Stanford C, Feine J, McGuire M (2016) Prospective assessment of CAD/CAM zirconia abutment and lithium disilicate crown restorations: 2.4 year results. J Prosthet Dent 116: 33-39.

- Lawson NC, Bansal R, Burgess JO (2016) Wear, strength, modulus and hardness of CAD/CAM restorative materials. Dent Mater 32: 275-283.