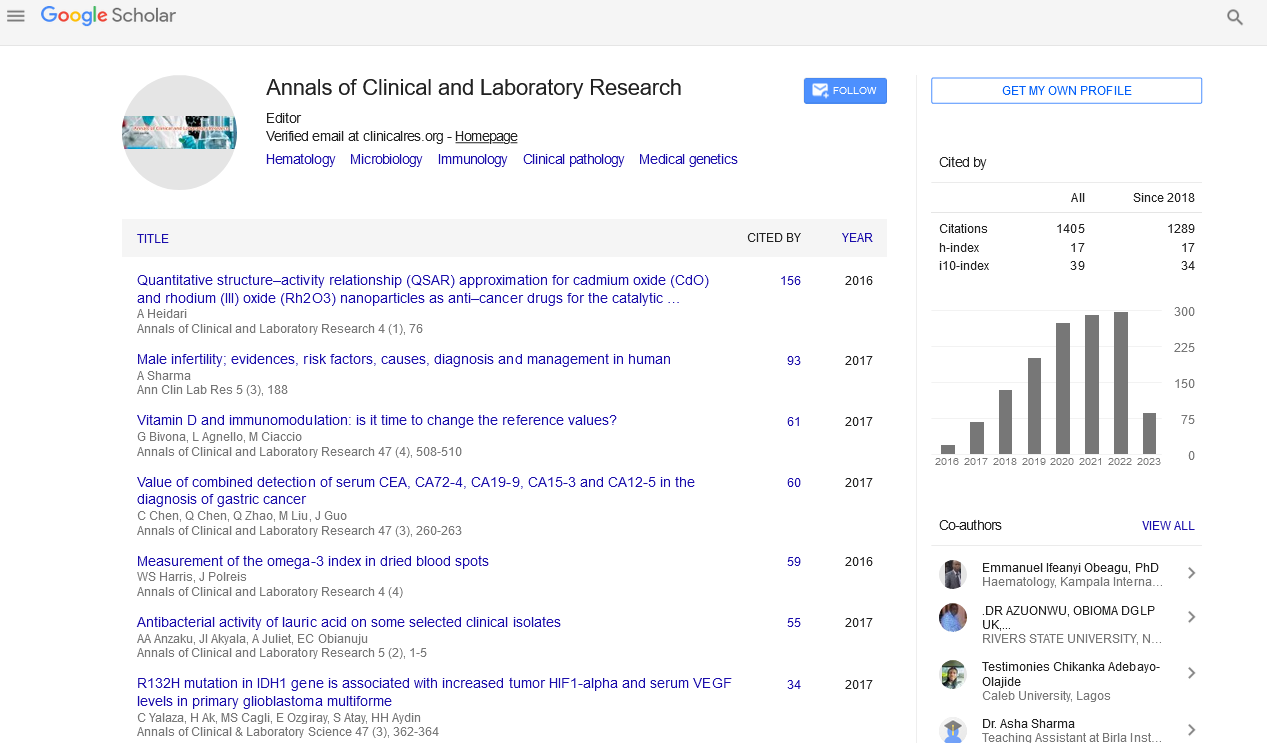

Commentary - (2023) Volume 11, Issue 3

The quality assurance processes in pharmaceutical analysis that ensuring safe and effective medication.

Angle Gurses*

Department of Pharmacology and Toxicology, University of Imam Abdulrahman Bin Faisal, Dammam, Saudi Arabia

*Correspondence:

Angle Gurses, Department of Pharmacology and Toxicology, University of Imam Abdulrahman Bin Faisal,

Saudi Arabia,

Email:

, Manuscript No. 13781;

, Pre QC No. 13781;

, QC No. 13781;

, Manuscript No. 13781;

Published:

29-May-2023, DOI: 10.36648/2386-5180.23.11.469

Abstract

Quality assurance is a critical component of pharmaceutical analysis, ensuring the safety, efficacy, and reliability of medications. This article highlights the significance of quality assurance in pharmaceutical analysis and its role in maintaining high standards throughout the drug development and manufacturing process. From method validation to equipment calibration and adherence to regulatory guidelines, quality assurance measures play a vital role in guaranteeing the integrity and effectiveness of pharmaceutical products

Keywords

Quality assurance, Pharmaceutical analysis, Drug safety, Method

validation, Equipment calibration.

Introduction

Pharmaceutical analysis serves as the foundation for evaluating

the quality and effectiveness of medications. It involves a wide

range of analytical techniques to assess drug identity, purity,

potency, and stability. However, ensuring the reliability and

accuracy of analytical results is paramount to guaranteeing

safe and effective medication. The quality assurance process

plays a crucial role in maintaining the highest standards in

pharmaceutical analysis, encompassing various practices and

procedures to verify the integrity and accuracy of analytical data

[1].

One of the key aspects of quality assurance in pharmaceutical

analysis is the validation and verification of analytical methods.

Method validation involves a rigorous evaluation of the

performance characteristics of an analytical procedure, including

specificity, accuracy, precision, linearity, and robustness. This

process ensures that the method is fit for its intended purpose

and provides reliable and reproducible results. Verification, on

the other hand, confirms that the analytical method is suitable for

its specific application within a given laboratory setting. Accurate

and reliable analytical results heavily rely on well-calibrated and

qualified equipment. The quality assurance process involves

regular calibration and qualification of analytical instruments

to ensure their proper functioning and accuracy. Calibration establishes the correlation between instrument readings and

known reference standards, while qualification verifies that

the instrument meets predefined performance criteria. Regular

calibration and qualification procedures help maintain the

accuracy and reliability of analytical measurements, minimizing

the risk of erroneous results [2, 3].

The pharmaceutical industry is subject to strict regulatory

guidelines and standards to ensure patient safety and product

quality. Quality assurance in pharmaceutical analysis involves

adherence to these regulatory guidelines, such as Good

Laboratory Practices (GLP) and Good Manufacturing Practices

(GMP). GLP provides a framework for conducting laboratory

studies and ensures the reliability, integrity, and validity of test

results. GMP outlines the quality control and quality assurance

measures necessary for the manufacturing and distribution

of pharmaceutical products. Adhering to these guidelines

ensures consistency, reliability, and safety throughout the drug

development and manufacturing process [4].

Quality assurance in pharmaceutical analysis also encompasses

the training and competency of laboratory personnel. Adequate

training ensures that analysts are proficient in performing

analytical techniques, understanding method protocols, and

adhering to quality assurance procedures. Ongoing training and

competency assessments help maintain the skills and knowledge

necessary for accurate and reliable analytical results [5].

Conclusion

Pharmacogenomics offers a revolutionary approach to drug

development and treatment, shifting the paradigm towards

personalized medicine. By understanding how an individual's

genetic variations influence drug response, healthcare professionals

can optimize drug selection, dosing, and therapeutic outcomes.

As research in pharmacogenomics continues to expand, it holds

the potential to transform the way we develop drugs, administer

treatments, and ultimately improve patient care and outcomes.

References

- Al-Khateeb A, Alomar MJ (2017). Subdural Hematoma and Delirium case evaluation in elderly patients. J Pharm Pharm Sci.9(2):299.

Indexed at, Google Scholar, Cross Ref

- Daniels VR, Bayuse TM, Mulcahy RA, Mcguire RK, Antonsen EL (2017). The pathway to a safe and effective medication formulary for exploration spaceflight. InHuman Research Program Investigators''Workshop.

Indexed at, Google Scholar

- Dhurjad P, Dhalaram CS, Ali N, Kumari N, Sonti R (2023). Metal–organic frameworks in chiral separation of pharmaceuticals. Chirality. 34(11):1419-36.

Indexed at, Google Scholar, Cross Ref

- Kebede B, Asredaw B (2000). Prescription Completeness, Rational Prescribing, and Dispensing Practice at Referral Hospital, Ethiopia. Age.619:100.

Indexed at, Google Scholar, Cross Ref

- Sarwar MH, Sarwar MF, Khalid MT, Sarwar M (2015). The Roles of Pharmacy and Clinical Pharmacy in Providing Healthcare Services to the People. J Pharm Pharm Sci.3(1):1-5.

Indexed at, Google Scholar

Citation: Gurses A (2023) The quality assurance processes in pharmaceutical analysis that ensuring safe and effective medication. Ann Clin Lab Res. Vol.11 No.3:469