Keywords

Chemical manufacturing and control (CMC); Ingredients; Drug; Pre-clinical; Clinical; Manufacturing process; Quality; Stability

Introduction

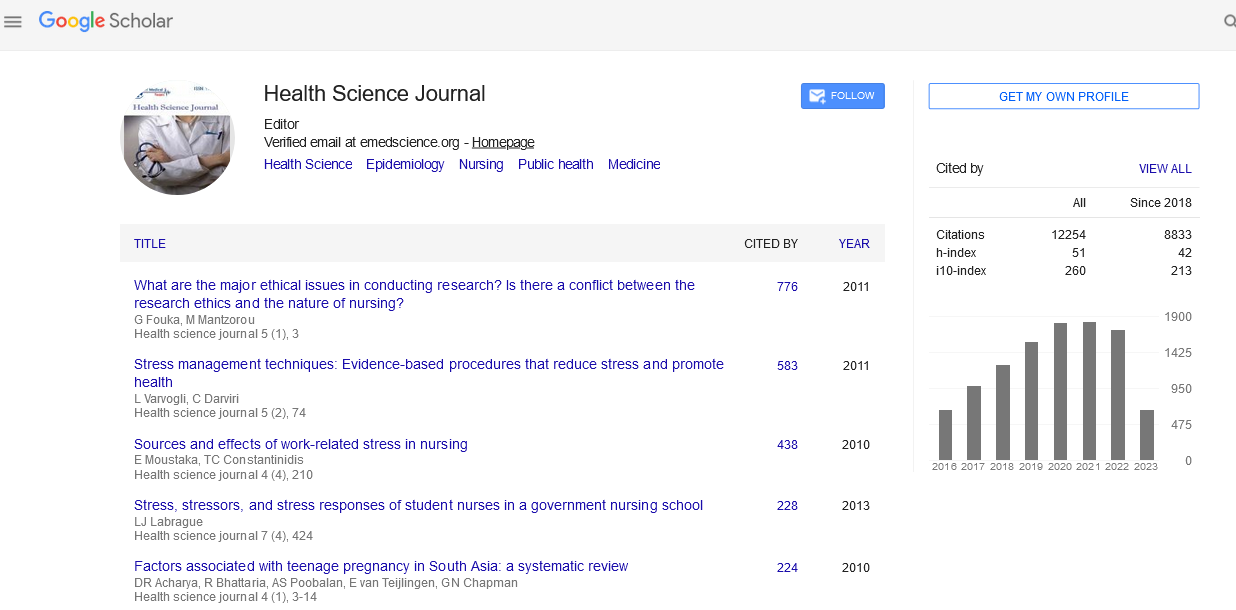

Various human diseases, coming with morbility and mortality, are the serious healthy problems to patients and huge challenges to drug researchers all over the world [1-3]. The needs for new drug development are always urgent and essential. However, the drug discovery and development is a complicated and time-consuming process with heavy cost expenses [4-6]. Chemical Manufacturing and Control (CMC) is essentially required for drug development. CMC, namely pharmaceutical study, generally includes products, production, technological process, impurity, quality, stability and drug formula. CMC is an important and necessary part of drug declaration materials and information [7,8]. A success of a new drug development needs to go through a long-term pathway from basic research, signal mechanisms, to druggable targets, from drug candidates, leading compounds, to clinical drugs, from laboratory bench works, pre-clinical trials, clinical trials, to drug marketing (Figure 1 and Table 1) [3,9,10]. Under this review, we will discuss the CMC and the different requirements of drug development in the different pre-clinical and clinical stages.

Figure 1 The major contents of chemical manufacturing and control (CMC) in drug development.

| Section |

Compound design |

Preclinical trial |

Phase I trial |

Phase?trial |

Phase ?trial |

| Chemical molecules and studies |

Determine the physicochemical properties of API;

Initial small-scale synthesis and supply (<100g)

|

Select the synthesis methods |

Establish suitable synthesis methods |

Determine the final synthesis methods |

Transfer API technology to manufacturers |

| Acquire the initial materials |

Acquire the initial materials |

Determine the suppliers of the initial materials |

Manufacture 3 batches of typical API products |

| Identify impurities and isomers |

Identify impurities and isomers |

Synthesis the reference substances of impurities and isomers |

Prepare the drug registration documents |

| Determine the possibility of drug synthesis |

Determine the possibility of scale-up synthesis |

Establish the scale synthesis methods |

--- |

| Prepare the drug synthesis for phase I studies |

Prepare the drug synthesis for phase II studies |

Acquire ICH stability data of API |

--- |

| ? |

Acquire ICH stability data of API |

? |

--- |

| Analytical methods and studies |

Drug description and evaluation; Drug analysis methods |

Develop the liquid phase methods for API and impurities |

Establish the liquid phase methods for API, impurities, and isomers |

Determine thes liquid phase method for API, impurities, and isomers |

Transfer the analysis methods of API and preparations to manufacturers |

| Develop the liquid phase methods for components and preparations |

Establish the liquid phase methods for drug preparation |

Determine the liquid phase methods for drug preparations |

Prepare the registration documents of analysis methods |

| Evaluate the liquid phase methods |

Develop the liquid phase methods for drug stability |

Establish and identify all analytical methods |

--- |

| Establish the initial standards of API and preparation |

Evaluate and identify the suitable liquid phase methods |

Establish the final standards of API and preparations |

--- |

| API: crystallinity and polycrystalline type |

Establish the standards of API and preparations |

? |

--- |

| Drug formulation and studies |

Toxicological studies;

Drug formulation |

Develop drug formulation for phase I study |

Develop drug formulation for phase II study |

Develop drug formulation for phase III study |

Transfer the preparation technologies to manufacturers |

| Study drug stability for phase I study |

Study the ICH stability for phase II clinical prescription |

Study the ICH stability for phase III clinical prescription |

Manufacture 3 batches of typical drug samples |

| Drug preparations for phase I study |

Drug preparations for phase II study |

Drug preparations for phase III study |

--- |

Table 1 CMC studies at different stages of new drug research and development.

CMC in the pre-clinical study

Before conducting clinical trials, pre-clinical study of tested drugs must be conducted and pre-clinical data must be provided, including compounds, the compositions, manufacturing process and quality control [7]. The pre-clinical data provided should meet the requirements for conducting the corresponding clinical trials of each phase. And also, the data on the efficacy and safety of the tested drugs and the ongoing clinical trials must be provided. The preparation of the tested drugs for clinical trials shall be under GMP condition and comply with the requirements of the national manufacturing and control standards of drugs in the countries where the drugs will be tested (Table 1) [11,12]. However, the tested drugs in pre-clinical study, to some extent, may not be required to be fully identical to that for the following clinical studies. In other words, the preparation of tested drugs for pre-clinical study may not be required to meet GMP standards. GMP standards are essential for drugs to be tested in clinical study, but not mandatory to pre-clinical study.

Dosage, formula and components of the tested compounds:

It is necessary to have a clear understanding of the properties of the tested compounds. On one hand, a comprehensive understanding of the properties of the compounds can provide the important information for selecting the used dosages, drug formula and components. On the other hand, the structures of the tested compounds have to be clearly defined, with its stability and the consistency in the follow-up studies. Because the pre-clinical studies belong to the initial stage in drug research and development, the tested dosages, drug formula and components may be changed with the deepening of drug studies. Meanwhile, while the specifications of the tested compounds are not clear, the design of drug dosage and formula should ensure the consistency of preparation and quality, and the controllable impurities on the premise of ensuring safety of the tested drugs [13,14]. The manufacturing process is basically carried out and is done in the laboratories. Generally, it is not necessary to optimize the process, but the impurities generated in the process, such as the by-products, organic solvents and heavy metals, must be effectively controlled.

Quality and stability of the tested compounds:

For the quality control, the universal methods are generally applied. For example, according to the general pharmaceutical requirements of active pharmaceutical ingredients (APIs), their production and preparations, the general and relevant methods are carried out to ensure the controllable quality of APIs [12,15]. For APIs, the testing items, testing methods and quality standards are determined according to the basic information of the initial materials, components, intermediates and impurities. It should be noted that the impurities and their contents of raw materials used for preparing the clinical samples, such as residual solvents or heavy metals, should fully meet the requirements of corresponding regulations and guidances. The pre-clinical studies at this stage need to provide the acceptable limit and maximal tolerance according to the experiemental safety data, and these limit and tolerance need to be supported by relevant experiments and the experimental data, such as the maximum solvent intake daily. Meanwhile, preliminary data are needed to confirm whether the stability of the prepared samples can support the subsequent product-related studies. CMC mainly ensures the controllability of drug quality [8,15]. For instance, the studies of stability of tested compounds need to guarantee that the quality and identity of the tested samples in the phase I clinical studies.

CMC in the clinical phase I study

At this stage, the key concern is to prepare sufficient products or APIs for the studies of pharmacology, toxicology, pharmacokinetics and others required for phase I studies [7]. It is very crucial to establish the whole production processes that can effectively control product quality, and the quality standards that are for the inspection and qualification of the products. CMC in this stage is to focus more on product quality and quality controllable (Figure 2) (Table 1) [3,7,16]. Then, the safety of subjects to receive the tested drugs is more concerned with the collection of the relevant pharmaceutical information.

Figure 2 The CMC process of the tested drugs in Phase I clinical studies.

Quality and stability of the tested drugs:

In phase I studies, we need to ensure the physical and chemical properties of the tested drugs that might be relevant to bulk manufacturing preparation and the impact factors such as crystal forms, solubility, stability, permeability and particle sizes. As for preparation process of the tested drugs, the entire technological process of the material preparation should be provided with the flow charts. Particularly, the solvents, reagents, catalysts and others applied in this stage should also be indicated. Generally, the manufacturing and technological process is not necessarily required for final verification. However, the sterilization, the sterilization process, aseptic environment and environmental cleanliness need to be satisfied for the aseptic and clean CMC requirements [14,16,17].

The quality control in this stage needs to establish the preliminary quality standards indicating production batches, quality standards, inspection items, analysis methods, impurities and the acceptable limits, quality comparison of representative batches of the products [7,12]. Particularly, the impurities of the tested drugs is critically concerned in this stage, including (1) analysis of impurities and the impurity spectrum based on the known knowledges, (2) the methodological verification of specificity and sensitivity of related materials and inspections, (3) analysis and control of potentially genotoxic impurities, solvent residues and elemental impurities that should comply with corresponding regulations and guidances [14,17].

As for the stability of the tested drugs, the experimental and clinical studies have to include such aspects as described here. The appropriate analysis methods are necessary and important, with the preliminary data of representative samples and other supporting data on stability such as the representative pictures, graphs, maps and spectrums of the key experiments and items. The stability-related data should support the physical and chemical parameters of the new tested drugs and meet the requirements during the planned clinical studies. Any supporting data can be provided if the planned experimental period is too short. On the basis of ensuring the stability of the tested drugs during clinical trials, we need to gradually accumulate stability data to support further clinical studies.

Reagents and preparations:

The dosage and formula of the prepared drugs, commonly used in phase I clinical studies are relatively simple so as to facilitate dose study and exploration. There are still a lot of uncertainties in the dosage, formula and prescription process. The pharmaceutical evaluation is not focused yet at this stage. The keypoint is to ensure the stability and safety of the tested drugs in clinical studies. The differences in the production and characteristics of the tested drugs and the relevant reagents used in clinical studies and used in toxicological studies should be specifically stated. Particularly, these differences may affect the safety of the tested drugs in order to ensure the identity of drugs used in pre-clinical animal experiments and clinical human studies [15,18].

The tested drugs will be determined and identified with their formula, compositions, dosage and the relevant factual basis. And the adjuvants in use should meet the corresponding medicinal standards, including elemental impurities, genotoxic impurities, endotoxins, microbes and microbial control [8,14]. In particular, the brand-new adjuvants that have not been used yet in preparations nationally and internationally should be declared as well. Sterilization, sterilization process, the related measurements and methods shall be verified for aspetic preparations of products. If unconventional preparations and the relevant technological processes are used in the drug manufacturing, these new methods should be studied in more details.

On information and storage conditions of packaging materials in direct contact, such as compatibility of packaging materials, and the new packaging materials with their new molecular structures or new uses, it is necessary to carry out serial experimental studies and provide the data and information correlated to further clincal review. The stability and compatibility of the tested drugs need to be evaluated when the compatible uses and certain special requirements such as syringes and catheters are applied in the reagent preparations [19-21]. Meanwhile, the manufacturers of the tested drugs used for phase I clinical trials are required to qualify and meet the national standards of “Good Manufacturing Practices for Drugs for Clinical Trials”. Their information including production, packaging, meansurement, inspection, and even the detail manufacturing address should be required and specified.

The situations for suspension of clinical trials:

According to the information provided in the pharmaceutical studies, clinical trials should be evaluated and suspended when there are certain concerns about drug safety or insufficient data for safety evaluation. The reasons for suspending clinical studies may include, but are not limited to, the following situations: 1) the new drug predicted from its chemical structures or the auxiliary materials used for preparations have the known toxicity or possibly potential toxicity; 2) the new drug can not likely maintain its stability during the whole clinical studies; 3) The impurity characteristics of the new drug show its potential toxicity, or the impurity whose content or component is above the identified limit or tolerance in the drug formula have not been fully identified and their potential toxicity has not been evaluated; 4) There is possibly a biosafety problem of animal-derived components; 5) The main cell bank or working cell bank has not been fully identified and evaluated.

CMC in the clinical phase II study

The tested drugs and preparation process:

More experimental evidence should be provided to reasonably support the chemical structures of compounds or APIs in order to prove the characterization of the tested drugs. The data of particle sizes, particle distribution and other physical properties such as polymorphic, liquid or solid types should be collected so as to establish the correlation of the informative data obtained in different stages of drug development (Table 1). If available, an updated technological process of synthesis or production should be provided in this stage, with the relevant flow charts or a detailed drug description. The updated technological process should cover the molecular structures of drugs, technological framework of production, reagents, solvents, auxiliary materials, the required equipments, manufacturing facilities, and the process descriptions for monitoring and controlling key products and production conditions.

In the production process, certain special steps should be described in more details. For instance, to materials or APIs producing from fermentation or originating from natural sources, each step related to safety during the production process should be firmly under control [8,16]. Viruses, microbes, impurities and their removal methods and protocols should be clearly described. The aseptic or sterilized procedures should also be very clear.

The control of quality and stability:

The quality standards should be updated with the latest version. The new standards of quality control should be described, indicating the changes in inspection items, acceptable limits, maximal tolerance, analysis methods, data comparison of the representative batches of the prepared products. Based on the analysis of the impurities and impurity spectrum by the known knowledges, we need to conduct the qualitative and quantitative analysis and reports on the newly generated impurities resulting from the changes of synthesis technological process or the maintenances of stability. At this stage, it is impractical to have a standard method that can be used to evaluate impurities to support NDA (New Drug Application). An appropriate evaluation system should be established based on production and production experiences, process stability and the relevant supportive data, safety and safety management [12,17,20,22]. For the analysis methods used but not officially recognized, there should be a complete description, the appropriate verification data, the relevant information and supportive data. For packaging materials with new materials used, new molecular structures and new uses, it is necessary to carry out the related experiments and provide collective data in the clinical reports.

For the stability at this stage, the serial experiments to analyze the stability of APIs should be provided to support APIs’ phase II clinical studies. These experiments should include specific experiments and the experiemtnal items, analysis and analysis methods, acceptable standards, the tested time and checkpoints, storage and the appropriate conditions, and other relevant projects or items [12,15,22]. Data revision and information update should provide the stability data of APIs used but not reported in phase I studies. All the stability data of APIs used in phase II clinical studies should be submitted in the annual reports. On the basis of ensuring the stability of drugs in clinical studies, further stability data should be gradually accumulated to support further clinical development.

The reagents and formula preparation

CMC studies in phase II need to describe the changes and provide the tested drugs, adjuvants, dosages, compositions and formula, with each item of quantitative components. However, there is no need to report the quantitative values of the parts not appearing in the production process or in the final products. As for the production process, an updated flow chart in the whole production process with brief description of each step shall be provided. And an update report for the aseptic preparations and sterilization should be submitted. The change of aseptic process such as changing terminal sterilization into aseptic production process should be provided, with no need to provide the verification and the related information of sterilization process. The difference of aseptic process between phase I and phase II should be clearly pointed out. Quality control, product stability and batch identity in the manufacturing process are still firmly required and recorded in the information reports [13,18,22]. Plus, the manufacturing process to provide the clinical products in this stage need to be clearly confirmed and strictly verified. Particularly, any difference from the production process used in phase I study such as addition, removal or change shall be reported in this phase II stage.

CMC in the clinical phase III study

Generally, the entire phase III clinical studies cost much more time and expenses, and much longer than phase I and II studies. Many more subjects are required in order to collect a large amount of clinical data and identify whether the tested drugs can benefit the subjects, and whether the tested drugs are safe without severe toxic side effects (Table 1). Therefore, CMC requirements and information provided in this stage are different from that in the ealier stages described above.

The tested drugs, preparation process:

All entire information of APIs in this phase III stage have to be provided, including molecular names, molecular structures, molecular weights, physical properties, chemical properties, biological properties and pharmaceutical properties. For instances, components, buffer and pH, binding affinity, stability, solubility, permeability, classification, hygroscopicity, dissociation constant, partition coefficient, crystal form, isoelectric point [8,22,23]. The specific requirements are different according to different types of the tested drugs. In addition to complete the entire process, flow charts, materials, material control and managements, it is necessary to provide the major changes that may affect drug quality and control in the technological preparation and production process compared to that in phase I and phase II clinical studies, and is also essential to assess the potential safety and risk accompanied with the changes of manufacturing process.

The control of quality and stability:

The CMC quality standards should have been well established in this late stage. The CMC requirements become more important and extremely detailed for the quality control, product identity, manufacturing stability [16,17,24]. The quality control needs to be considered at least in the following aspects.

(1) Reagents and preparation control: The qualification standards of products or reagents, and the valid date or expired date need to be provided in any type of form, table, graph and chart, including the inpection items, inspection methods, method types, provisional limits, maximum tolerance, and minimum efficacy. The changes of quality standards in phase III are listed out, specially in comparison with standards in phase I and phase II. For example, the reasons should be given if the changes are related to loose standards, cutting items, and less restrictions. Especially, the supporting information and necessary evidence have to be provided if there are certain critical changes in the technological process or the manufacturing strategies.

2) Adjuvant control in the formula: Once the changes of the adjuvants occur in the drug formula, the references of quality standards to phamaceutical adjuvants should be provided. More detailed information such as inspection items, maximum tolerance, and analysis methods, should be provided for non-phamaceutical adjuvants.

3) Analysis of impurity: the analysis of impurities and impority spectrum based on the known knowledges will focus on the studies of degradation, degradation path and degraded products. At the same time, the information and data of degradation should be updated so that safety evaluation can be carried out.

4) For non-recognized or unofficially analysis methods, there should be a fully integral description supported with the appropriate verification data.

5) The updated batch and analysis summary: This section covers serial manufacturing batches of products including non-clinical safety batches of products, phase I batches of products and phase II batches of products, batches of studying stability and formula, phase III batches of products and the relevant inspection reports. Moreover, the batch number, batch size, prescription technology, manufacturing process, production places, production date, purposed uses, analysis methods, control limit or maximum tolerance, measurements and outcomes shall be indicated [12- 14,24].

And also, there are certain specific and detailed requirements for stability of products used in this clinical studies. The results of studying stability to support phase III clinical trials will be provided. Based on the characteristics of the tested drugs, it may also be necessary to provide stability information under the conditions of high temperature, high humidity, light, oxidation, low temperature, repeated freezing and thawing [16,22]. Based on these results, the storage of clinical products and the suitable storage conditions will be optimized. For the products that need to be diluted and compatible, it is necessary to provide the information of stability after dilution and compatibility. For multi-dose packaging except oral and solid products, it is necessary to provide the necessary information of stability after the package being open. To ensure sufficient stability data in the NDA stage, it is suggested to provide formal stability experiments and experimental design.

Reagents, formula and manufacturing process:

For the study of drug formula in phase III, products and their formula compositions are provided with dosage, unit and usage, and included with the name, dosage, function and components of the adjuvant materials [8,13]. If pre-mixed adjuvant materials are used, their compositions should be fully defined, and the compositions of packaging or coating materials and capsules should be clearly verified at maximum extent. The ingredients used in the preparation but eventually removed should also be formally listed. For special formula or preparations such as inhalation and nasal spray, these specific drug delivery devices should be identical to those of commercial products.

The manufacturing process in this stage will have been settled down and be identical to that for the eventual commercial production. The changes of the production process shall be updated and provided with the changed flow charts and brief descriptions. The updated information on the aseptic preparations of drugs in phase I study, and the change of sterilization process in phase II study should be described and verified in this phase III study. It is also a need to briefly describe the development process of dosage, formula, specification, prescription and technology. For the special drug preparations, such as inhalation, syringes, ophthalmic preparations, oral liquid, nasal spray, with the high risks of the interactions of the packaging materials, it is necessary to provide the information of the compatibility of materials [14,18,25,26]. For products that need to be temporarily prepared, different to the ready-to-use drug, it is necessary to study and understand the compatibility, stability, dilution and preparation methods. For drug given to the specific population such as children, all the given drugs, compositions, dosages, formula and drug delivery devices should be safe and suitable for the specific subjects. All manufacturers related to the production of drugs used for phase III have to be listed with their names and complete addresses. There should include all the manufacturers related to production, packaging, inspection and quality control. If more than one mannufacturers are involved in, the responsibilities of each of them should also be listed.

Conclusion

New drug development is time-consuming and huge expensive with a high risk and a low success[8]. There is a little chance to smoothly complete all the studies, successfully pass FDA approval and eventually bring a drug into market [12]. The chemical manufacturing and control (CMC) always accompany with the entire process from pre-clinical study, phase I clinical study, phase II clinical study to phase III clinical study, and plays a crucial role in the new drug development [1,17]. The quality control of products, removal of impurity and the establishment of technological standards during CMC process of production and management can ensure the identity and qualification of the tested drugs in all pre-clinical and clinical trials and maximally guarantee solid and trustable clinical data which are so significant to evaluate a potential drug and enhance a little valuable chance of the drug to succeed.

39459

References

- Sung H, Ferlay J, Siegel RL, Laversanne M, Soerjomataram I, et al. (2021) Global cancer statistics 2020: GLOBOCAN estimates of incidence and mortality worldwide for 36 cancers in 185 countries. CA Cancer J Clin 71: 209-249.

- Sun LC, Coy DH (2011) Somatostatin receptor-targeted anti-cancer therapy. Curr Drug Deliv 8: 2-10.

- Frapaise FX (2018) The End of Phase 3 Clinical Trials in Biosimilars Development? BioDrugs 32: 319-324.

- Wang X, Wang R, Kang Q, Bai L (2020) The Antitumor Agent Ansamitocin P-3 Binds to Cell Division Protein FtsZ in Actinosynnema pretiosum. Biomolecules 10: 699.

- Sun L, Coy DH (2016) Somatostatin and its Analogs. Curr Drug Targets 17: 529-537.

- Shaw APM, Wint GRW, Cecchi G, Torr SJ, Mattioli RC, et al. (2015) Mapping the benefit-cost ratios of interventions against bovine trypanosomosis in Eastern Africa. Prev Vet Med 122: 406-416.

- Tanyous JN (2018) Cleaning Validation: Complete Guide for Health - Based Approach in Chemical Cross - Contamination Risk Assessment. PDA J Pharm Sci Technol 73: 204-210.

- Abrantes CG, Duarte D, Reis CP (2016) An Overview of Pharmaceutical Excipients: Safe or Not Safe? J Pharm Sci 105: 2019-2026.

- Fuselier JA, Sun L, Woltering SN, Murphy WA, Vasilevich N, et al. (2003) An adjustable release rate linking strategy for cytotoxin-peptide conjugates. Bioorg Med Chem Lett 13: 799-803.

- Lei J, Sun L, Huang S, Zhu C, Li P, et al. (2019) The antimicrobial peptides and their potential clinical applications. Am J Transl Res 11: 3919-3931.

- Zigler SS (2009) Instrumentation and radiopharmaceutical validation. Q J Nucl Med Mol Imaging 53: 402-410.

- Janvier S, Cheyns K, Canfyn M, Goscinny S, De Spiegeleer B, et al. (2018) Impurity profiling of the most frequently encountered falsified polypeptide drugs on the Belgian market. Talanta 188: 795-807.

- Sarraguca MC, Ribeiro PRS, Santos AOD Lopes JA (2015) Batch Statistical Process Monitoring Approach to a Cocrystallization Process. J Pharm Sci 104: 4099-4108.

- Markovic I (2007) Evaluation of safety and quality impact of extractable and leachable substances in therapeutic biologic protein products: a risk-based perspective. Expert Opin Drug Saf 6: 487-491.

- Murray-Smith RJ, Coombe VT, Grönlund MH, Waern F, Baird JA, et al. (2012) Managing emissions of active pharmaceutical ingredients from manufacturing facilities: an environmental quality standard approach. Integr Environ Assess Manag 8: 320-330.

- Bommi S, Jayanty S, Tirumalaraju SR, Bandaru S (2020) Quality by Design Approach to Develop Stability Indicating Method to Quantify Related Substances and Degradation Products of Sacubitril by High Performance Liquid Chromatography. J Chromatogr Sci 58: 844-858.

- Zhou Z (2016) Non-target impurity profiling of marketplace Cetirizine using high-resolution mass spectrometry and multivariate data analysis. Rapid Commun Mass Spectrom 30: 1941-1950.

- Garcia-Arieta A, Torrado-Santiago S, Goya L, Torrado JJ (2001) Spray-dried powders as nasal absorption enhancers of cyanocobalamin. Biol Pharm Bull 24: 1411-1416.

- Ang CYW, Hu L, Heinze TM, Cui Y, Freeman JP, et al. (2004) Instability of St. John's wort (Hypericum perforatum L.) and degradation of hyperforin in aqueous solutions and functional beverage. J Agric Food Chem 52: 6156-6164.

- Assaf J, Gomes DZ, Wuest B, Parr MK (2017) Photostability testing using online reactor HPLC hyphenation and mass spectrometric compound identification illustrated by ketoprofen as model compound. J Pharm Biomed Anal 145: 414-422.

- Mohammad A, Yang Y, MA, Faustino PJ (2015) A long-term stability study of Prussian blue: A quality assessment of water content and cesium binding. J Pharm Biomed Anal 103: 85-90.

- Mohammad A, Yang Y, Khan MA, Faustino PJ (2015) Long-term stability study of Prussian blue-A quality assessment of water content and cyanide release. Clin Toxicol (Phila) 53: 102-107.

- Antonio M, Calvo NL, Maggio RM (2019) Chemometric study of the excipients' influence on polymorphic-behavior. Mefenamic acid as case of study. J Pharm Biomed Anal 170: 8-15.

- Yekpe K, Abatzoglou N, Bataille B, Gosselin R, Sharkawi T, et al. (2018) Developing a quality by design approach to model tablet dissolution testing: an industrial case study. Pharm Dev Technol 23: 646-654.

- Lintz W, Barth H, Osterloh G, Schmidt-Böthelt E (1998) Pharmacokinetics of tramadol and bioavailability of enteral tramadol formulations. 3rd Communication: suppositories. Arzneimittelforschung 48: 889-899.

- Han M, Fang XL (2006) Difference in oral absorption of ginsenoside Rg1 between in vitro and in vivo models. Acta Pharmacol Sin 27: 499-505.